chubbza5

Member

- Thread Starter

- #81

Yeah there's tons of room back there with no seat!! I want to keep it under the seat, it's sort of become a "lets see how much we can do with so little" project.

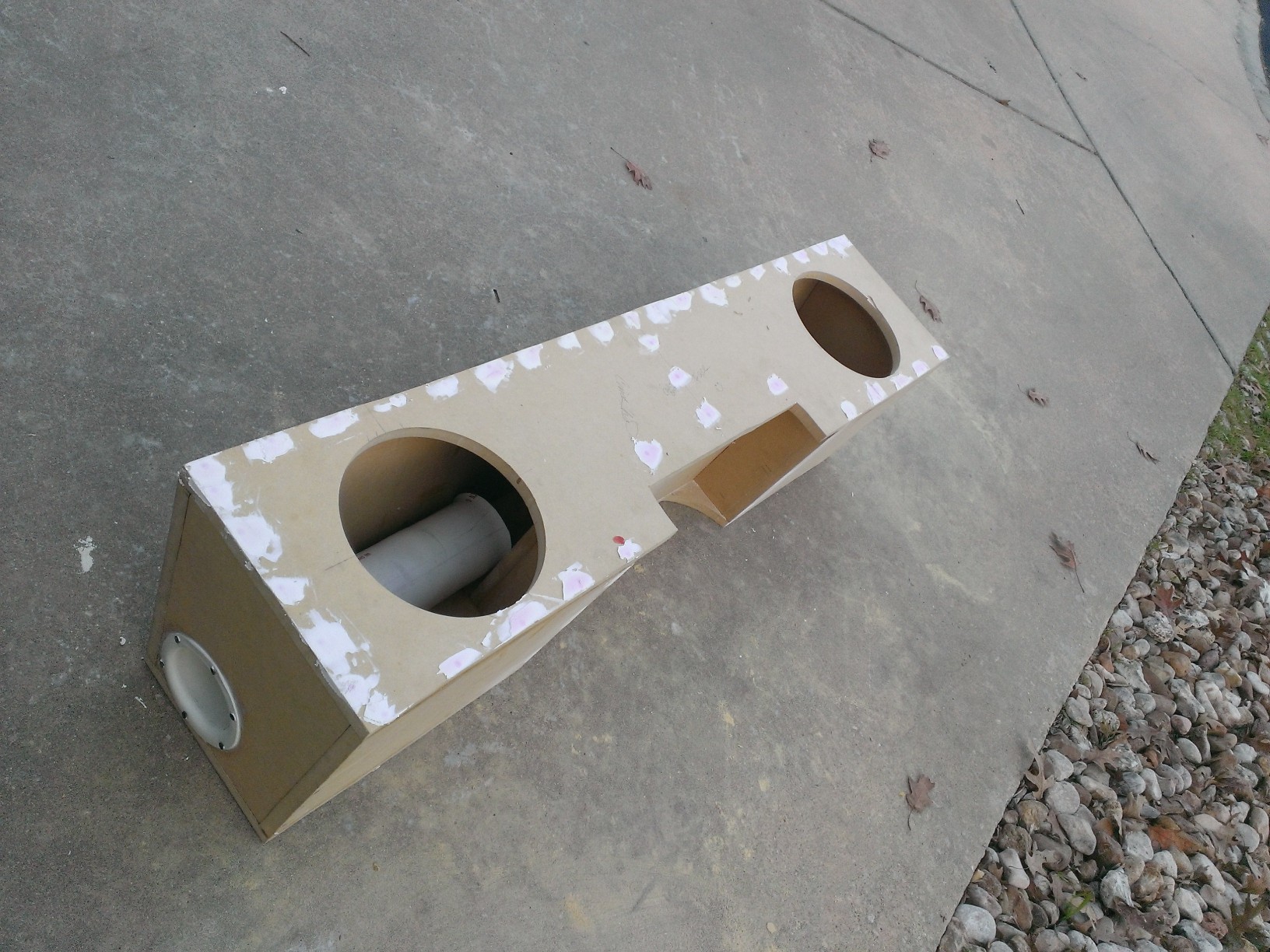

The bracket on the passenger side won't be in the way at all since it's up on the little shelf. The driver side bracket will be right against the box. The ports were going to be a bit offset towards the front/top portion of the box with 90* elbows on them to put them opening towards the back wall of the box. They're only like 9" long each.

If I have to make one side of the box a bit shorter because of the bracket, I will adjust the box divider that will be on top of the transmission hump a bit towards the other side to keep volumes equal.

Budget on the amp was $200 or so, but I've never realized how much high power reliability costs. I've gotten deals from cadence in the past that were at cost so I never thought about what it really costs to go 1000w+ That amp is $270, So it's above what I wanted to spend but I think I will be much happier. I was looking at the PPI amps, but since they sold out I don't really trust it. IT's in the soundstream/power acoustik family.

Do you think that true 1500rms would be fine on two 1200w reccomended rms speakers? It's about 60% power to each (at least). I have ordered the speakers. For the price (sub 300) I can't find any amps with a good reputation and proven numbers that are anywhere near 1500w.

The bracket on the passenger side won't be in the way at all since it's up on the little shelf. The driver side bracket will be right against the box. The ports were going to be a bit offset towards the front/top portion of the box with 90* elbows on them to put them opening towards the back wall of the box. They're only like 9" long each.

If I have to make one side of the box a bit shorter because of the bracket, I will adjust the box divider that will be on top of the transmission hump a bit towards the other side to keep volumes equal.

Budget on the amp was $200 or so, but I've never realized how much high power reliability costs. I've gotten deals from cadence in the past that were at cost so I never thought about what it really costs to go 1000w+ That amp is $270, So it's above what I wanted to spend but I think I will be much happier. I was looking at the PPI amps, but since they sold out I don't really trust it. IT's in the soundstream/power acoustik family.

Do you think that true 1500rms would be fine on two 1200w reccomended rms speakers? It's about 60% power to each (at least). I have ordered the speakers. For the price (sub 300) I can't find any amps with a good reputation and proven numbers that are anywhere near 1500w.