Updating you guys on what's going on.

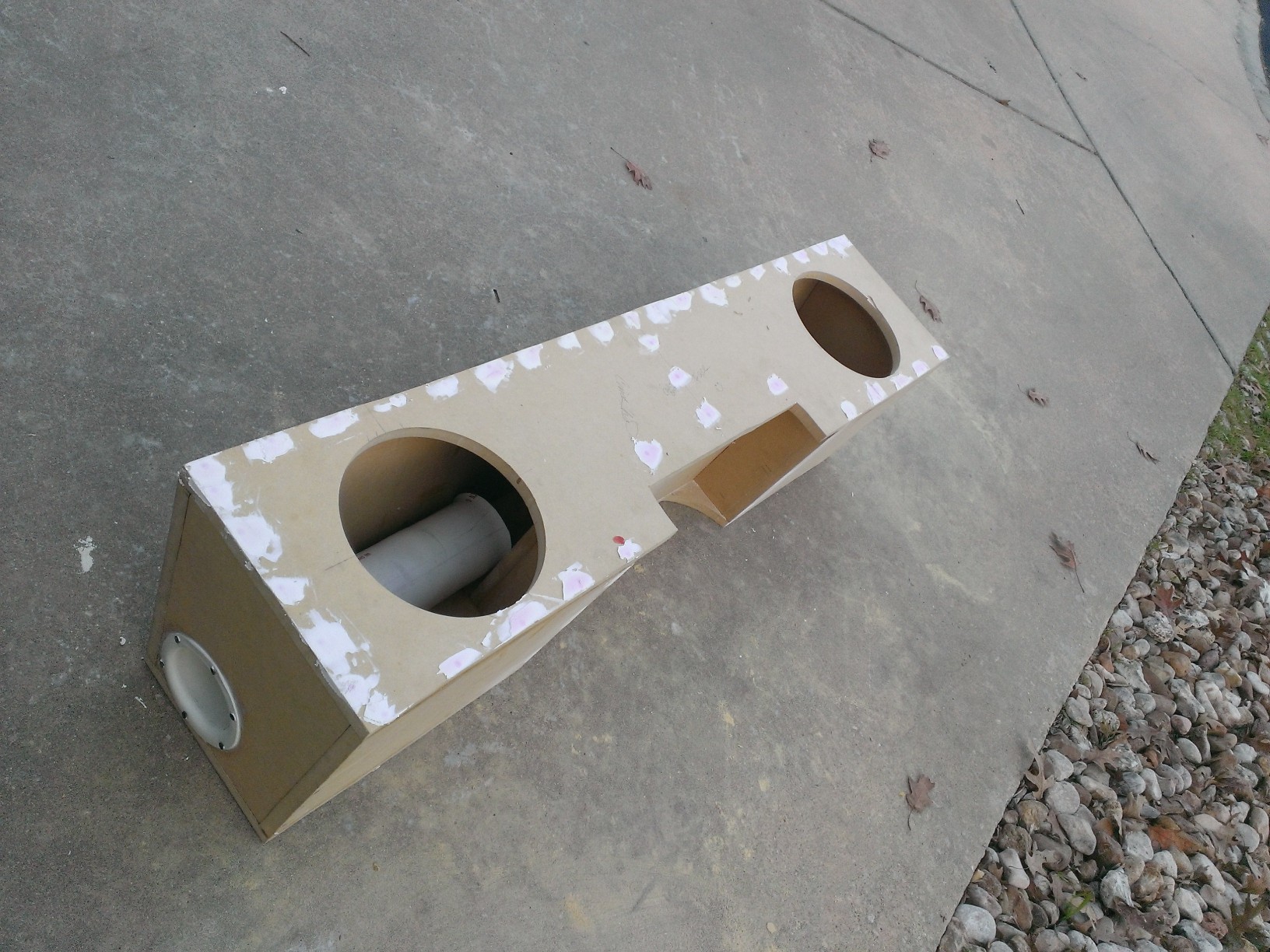

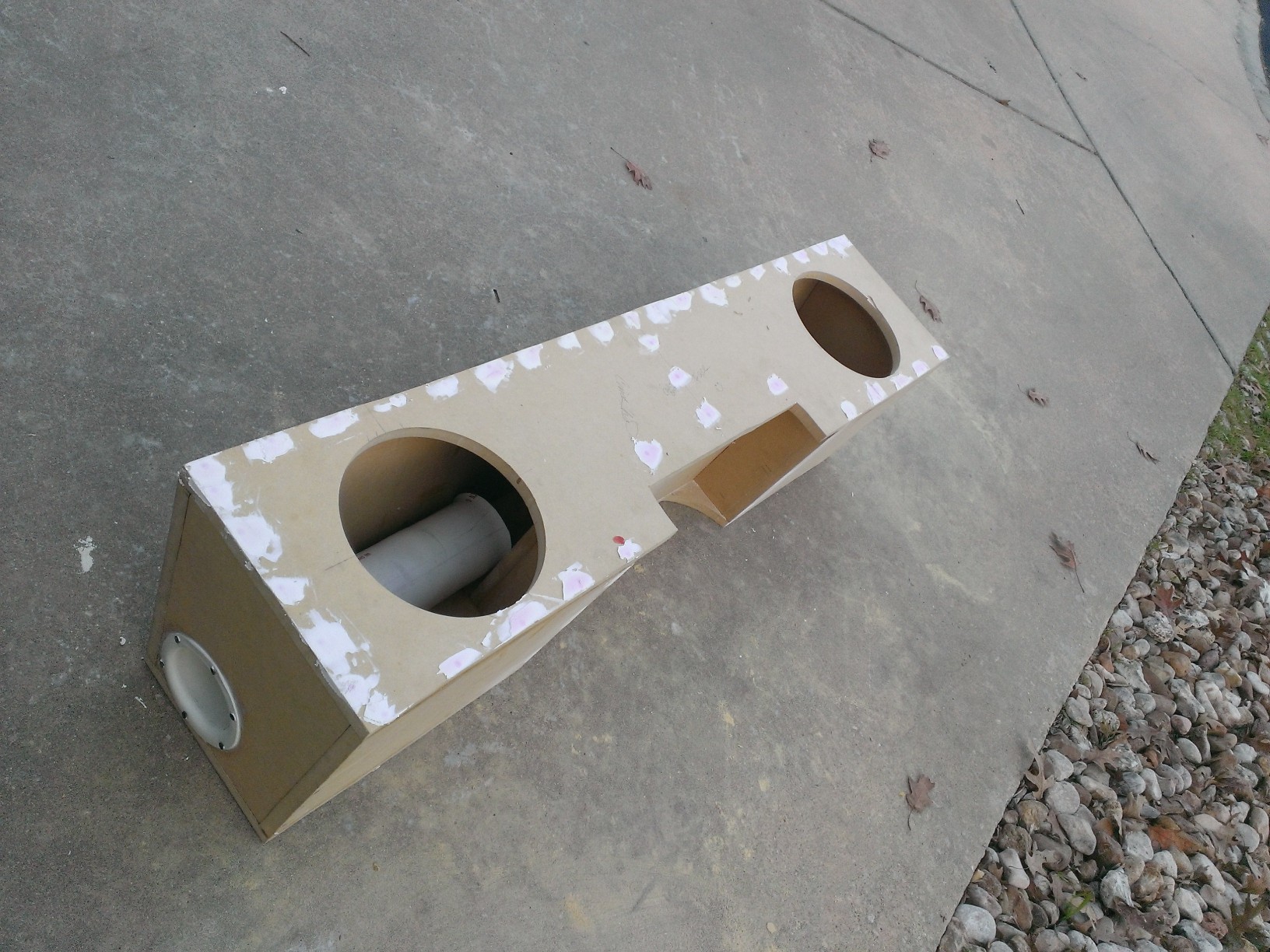

I finished the overall shape of the box and have finished one side. Dimensions came out a LITTLE different due to GM's wavy *** floor, but still got a gross 1.33 per side.

It's a 4" port, 17"~ long flared with a home made PVC + heat gun port. I have started putting filler over all of my screw holes and I've glued and sealed all internal edges. Only bad part about the port is it's impossible for me to have a 4" port, 4" away from all interior walls (diamater away is reccomended). I know they can be less than 1" away but more is better. It's about 2" from opening because the port ends right above the transmission hump on both sides. So the transmission hump volume will sort of act as a buffer/extended port because of the way it sits. I tuned for 34hz but I know it will probably end up lower because of the way it's designed. Came out to about 1.13 cubes net. Small but sturdy as hell! I used a 4" instead of 3" to avoid port noise. Since it will be close to wall either way, I'd rather just make it a larger port to make sure it won't chuff. I used a metal IKEA lamp shade to do the flare, then pushed it against the ground to make it flat. No fancy setup needed!

This project has to be good, I bled all over the box. Blood sweat and beers right?

The sub magnet is about 2.5" away from the PVC tube, although it looks like it would be closer.

Also got one of the hds310's in the mail. Waiting on sub

#2 and the SKAR amp to come in!

I'll post pics tomorrow!

Side note: I'm thinking of using some 8 gauge wire as speaker wire since I have a bunch laying around and I don't feel like going and buying some 12 just to wire them. Anyone see any problems with this?

Also, when I put the wires in the speaker terminals from the outside in, it has a hard time fitting through the subwoofer hole in the face. Is it ok to run the wires from the center of the sub, through the sub terminals outwards instead of inwards?