You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

-

20Participant count

-

Participant list

hispls 5,000+ posts

CarAudio.com Veteran

- Thread Starter

- #17

At this point I'd call it "open source". Please just report back if you come up with any improvements.I've never seen a kerfed port built like that...I like it, gonna steal your idea

Actually haven't really looked over the motors yet, but they seemed intact enough. Fortunately USPS hand sorts really heavy stuff so it's not like they're dropping from a 20 foot high conveyer belt like at UPS or FedEx

The_Grimy_One 10+ year member

CarAudio.com Veteran

hispls 5,000+ posts

CarAudio.com Veteran

- Thread Starter

- #20

I was actually thinking about cement in the gaps there. May buy some spray foam just in case, but there's CA glue + liquid nails there and I plan to do more liquid nails around the edges when I finish it up. What with and if I fill it at all will depend on how solid it seems tomorrow when everything is set.my only concern is having air getting inbetween the kerf there and flapping around the pieces...just make sure its sealed off nice and tight, maybe try some expanding foam too to help make it sturdier

hispls 5,000+ posts

CarAudio.com Veteran

- Thread Starter

- #21

Still waiting on coils and such. Box is coming along nicely. Got the baffle made (3 layers... I plan to flush mount the subs when I can get a 5/8" rabbet bit) and mounted filled the gaps (silly idea... a big mess and they are really solid anyway).

Did bondo and sanding and mostly painted inside the port. Tomorrow I'll put in the 2" hardwood bracing and finish off the last side. Some rounding, smoothing, and hopefully have the subs in it by the end of the week.

Did bondo and sanding and mostly painted inside the port. Tomorrow I'll put in the 2" hardwood bracing and finish off the last side. Some rounding, smoothing, and hopefully have the subs in it by the end of the week.

Gbob2003 10+ year member

Great Odens Raven

So im kinda thinking about doing the same thing. What did you use to fill the sono tube gap? I was thinking about sealing the lip of the tube with some bondo then filling the outside and inside cap with some yellow foam. Did you use 6" or 8" tube? I really like this idea. Ill be sure to throw in my sig that it was your awesome idea //content.invisioncic.com/y282845/emoticons/biggrin.gif.d71a5d36fcbab170f2364c9f2e3946cb.gif Im gonna make it for 2 obsidian audio 12s

hispls 5,000+ posts

CarAudio.com Veteran

- Thread Starter

- #23

That's a 12" sono tube. I'm sure you could use it with any size. I used expanding/spray foam to fill between the pieces of tubes. Probably unnecessary. On the port and baffle side, rabbeting out the width of the tube and sandwiching the tube piece between the two layers of wood is really solid, in the edge pieces if I were to do it again I'd just glue and use a staple gun. When the edges of the tube are fastened to something it has a lot of strength. I think the walls of the box would be much more likely to flex than the corners that I rounded over (even with the bracing).So im kinda thinking about doing the same thing. What did you use to fill the sono tube gap? I was thinking about sealing the lip of the tube with some bondo then filling the outside and inside cap with some yellow foam. Did you use 6" or 8" tube? I really like this idea. Ill be sure to throw in my sig that it was your awesome idea //content.invisioncic.com/y282845/emoticons/biggrin.gif.d71a5d36fcbab170f2364c9f2e3946cb.gif Im gonna make it for 2 obsidian audio 12s

I really like the way the sono tube slices round over internal edges and plan to use that method in future.

//content.invisioncic.com/y282845/emoticons/yumyum.gif.0556df42231b304b9c995aefd13928a8.gif:yumyum:

Got the box braced and assembled. Time for a couple lobster rolls for lunch (notice how we use New England style rolls *split at top* for a proper lobstah roll)

More pics later.

hispls 5,000+ posts

CarAudio.com Veteran

- Thread Starter

- #26

The rest of the softparts and the baskets showed up today. This is the new Shocker coil. Dual 2.8 ohm aluminum and very long. I'd say a good inch and a half more WW than the dual 1.4s. Also got some nice little rings to reinforce the suspension.....can't hurt. Also note these RE terminals actually function with a sig motor (push style don't clear the motor on 12 spoke baskets)

hispls 5,000+ posts

CarAudio.com Veteran

hispls 5,000+ posts

CarAudio.com Veteran

hispls 5,000+ posts

CarAudio.com Veteran

- Thread Starter

- #29

Amps are not on the box, but on a vertical mounted rack. I will angle that at some point.

I punched a couple holes through one of the surrounds screwing them in.... It's all good since I didn't really like the way that one came out anyway. I'll use it til it breaks and build up another one in the meantime.

Lots of cosmetic stuff I want to take care of, starting with flush mounting the subs. Nobody around here has a 5/8 rabbeting bit so that will wait. Also I want to round over edges, fill screw holes, sand and finish painting.

I think this ended up tuning a bit lower than I expected. Response is quite linear from 35 to 70 cycles, my peak seems to be very high now too (probably a function of impedence rise...which is my main concern with these coils). I really wanted to get 4 in there to get down to 1.4 nominal (which I know that amp likes), but I really don't have the space to do it right. I'm sure I'm losing on the meter but it sounds really loud and nice.

Would sell these subs for 325+ shipping each if anyone is interested.

I punched a couple holes through one of the surrounds screwing them in.... It's all good since I didn't really like the way that one came out anyway. I'll use it til it breaks and build up another one in the meantime.

Lots of cosmetic stuff I want to take care of, starting with flush mounting the subs. Nobody around here has a 5/8 rabbeting bit so that will wait. Also I want to round over edges, fill screw holes, sand and finish painting.

I think this ended up tuning a bit lower than I expected. Response is quite linear from 35 to 70 cycles, my peak seems to be very high now too (probably a function of impedence rise...which is my main concern with these coils). I really wanted to get 4 in there to get down to 1.4 nominal (which I know that amp likes), but I really don't have the space to do it right. I'm sure I'm losing on the meter but it sounds really loud and nice.

Would sell these subs for 325+ shipping each if anyone is interested.

Gbob2003 10+ year member

Great Odens Raven

So would you be able to maybe put up a parts list of everything you needed? I would be very thankfull //content.invisioncic.com/y282845/emoticons/smile.gif.1ebc41e1811405b213edfc4622c41e27.gifThat's a 12" sono tube. I'm sure you could use it with any size. I used expanding/spray foam to fill between the pieces of tubes. Probably unnecessary. On the port and baffle side, rabbeting out the width of the tube and sandwiching the tube piece between the two layers of wood is really solid, in the edge pieces if I were to do it again I'd just glue and use a staple gun. When the edges of the tube are fastened to something it has a lot of strength. I think the walls of the box would be much more likely to flex than the corners that I rounded over (even with the bracing).

I really like the way the sono tube slices round over internal edges and plan to use that method in future.

Activity

No one is currently typing a reply...

Similar threads

Be sure to see the sub specs. It should tell you the ideal sealed enclosure size.

- Started by vlusardi

- Enclosure Design & Construction

- 3

- 163

FEATURED

'99 Jeep TJ audio project

TBH, that is too many speakers for just a pair of 10" subs. The Skar 6.5s and tweeters are very efficient and can get super loud on moderate...

- Started by TommyK

- Car Audio Build Logs

- 6

- 633

I purchased a set of 1" stand off rings, should still be good from door to cone as well. They won't fit without the spacers, the recoils I...

- Started by Grimmjoww

- Car Audio Build Logs 2 3

- 30

- 8K

It is the same one that Rockford Fosgate sells as well. They are identical and the NVX is cheaper as well. Even Amazon has them iirc for 199.99...

- Started by JasoninDLH

- General Car Audio

- 12

- 1K

Is anyone familiar with, or can help with the Infinity system (with amp) fitted in 2001 Jeep Grand Cherokee?

I've installed a Atoto A6 head unit...

- Started by Ken_ES

- General Car Audio

- 0

- 799

About this thread

- Start date

- Participants

- Who Replied

- Replies

- 70

- Views

- 11,888

- Last reply date

- Last reply from

- RangerDangerV2

Latest topics

-

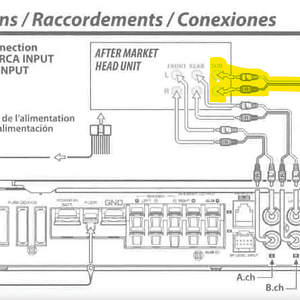

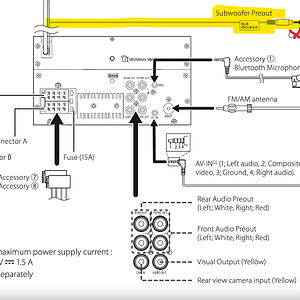

Question about connections between head unit (HU), amp, and sub

- Started by kanihoncho

- Replies: 3

-

Does this amp/speaker combo work well for both sets of speakers?

- Started by kanihoncho

- Replies: 4

-

-

-