You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

-

5Participant count

-

Participant list

Jimi77 5,000+ posts

CarAudio.com VIP

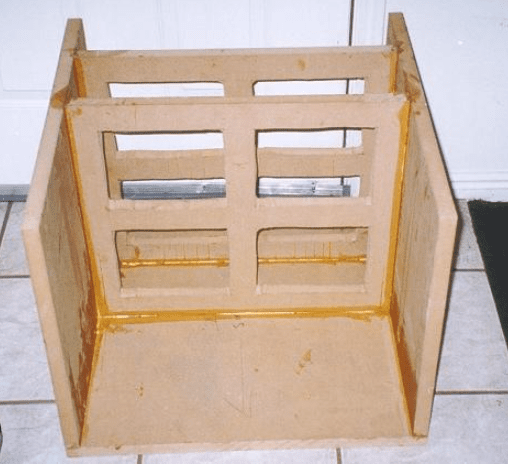

The port and the subs should be on the same side (Yes, that is the speaker baffle). This allows the sub and the port to couple acoustically. In instances where you can't, then the opposite wall would be the next best thing. 2 evenly spaced (unlike the picture) braces should be placed equidistant from the middle and sides internal internal braces would be fine. Like this (but spaced as noted and with the sub placement in mind, at least one in the middle):

1 large flared round port is best as it is poses the least friction for moving the air and the dual flares like a Precision port or aero port, reduce chuffing (wind noise or farting)

For the two of the BlackBrick subs you're going to use tune to 32Hz:

blackbrickaudio.com

blackbrickaudio.com

The following measurements' include considerations for the woofer, port and brace displacements.

Slot loaded box:

4"Wx10"Hx14"D slot loaded box:

You'll need a 5.75 internal cubic feet. I always recommend a 3/4 inch roundover edge on the extremal port area.

6"Dx10"L Round flared precision port port box:

You'll need a 5.5 internal cubic foot box.

For determining how to cut the port length, follow these guideline.

* - The value for Flare Length Port Required is the overall length of the flared port. If you specified more than one port for the Number of Ports value the Flare Length Port Required value will be for each port.

* - For the 6" Precision Ports cut the center tube 6 inches shorter than the Flare Length Port Required value.

1 large flared round port is best as it is poses the least friction for moving the air and the dual flares like a Precision port or aero port, reduce chuffing (wind noise or farting)

Home

Precision Port 6" Flared Port Tube KitThe unique flared-end construction of the Precision Port™ system enables it to outperform any standard port tube on the market. Conventional tubes suffer from nasty turbulence at the entrance and exit of the port, producing unwanted noise and poor sound...

For the two of the BlackBrick subs you're going to use tune to 32Hz:

BRICKHOUSE 12" Subwoofer

Our largest, most powerful 12" woofer is finally here! Weighing in at 71lbs, this monster wont let you down. Period. Now with a black motor.

The following measurements' include considerations for the woofer, port and brace displacements.

Slot loaded box:

4"Wx10"Hx14"D slot loaded box:

You'll need a 5.75 internal cubic feet. I always recommend a 3/4 inch roundover edge on the extremal port area.

6"Dx10"L Round flared precision port port box:

You'll need a 5.5 internal cubic foot box.

For determining how to cut the port length, follow these guideline.

* - The value for Flare Length Port Required is the overall length of the flared port. If you specified more than one port for the Number of Ports value the Flare Length Port Required value will be for each port.

* - For the 6" Precision Ports cut the center tube 6 inches shorter than the Flare Length Port Required value.

Products Menu

www.psp-inc.com

Last edited:

You gots the volumes/configurations above, have at it! Sounds like it's going to jam!Gonna get a couple of the black brick brickouse 12's. My box can be max 16" high and 39" wide. Depth is to be determined accordingly to the volume airspace needed. If the subs and port need to be on the same side then that will be great. I will fire them into the cabin through the cutout behind the rear seat.

Activity

No one is currently typing a reply...

Similar threads

For around 1k rms I’ll double up 1/2” for a 1” thickness all around. If doing a flush sub look I’ll add another .75” baffle depending on how tall...

- Started by Original wis

- Enclosure Design & Construction

- 3

- 2K

just use riv-nuts or clip-nuts, made for blind fastening. some window weld should hold the ring on there pretty good..... being 4x6, you could...

- Started by HardofWhoring

- Enclosure Design & Construction

- 4

- 1K

I say go for it. Just add some kind of bracing to the bigger panels. Some old home speaker boxes were made of 3/8" mdf. Maybe not even mdf, some...

- Started by Drifter mike

- Subwoofers

- 1

- 921

Yea. That's what I did. I mixed the glue with the dust from sanding and fill in the bigger holes. Then filled the rest with wood filler..works awesome

- Started by GoT_2B_BuMpN

- Enclosure Design & Construction

- 9

- 3K

Yes

Should be easy with a flush trim bit in a router and will allow OP to hide any screws/nails used along edges.

- Started by Blackout67

- Enclosure Design & Construction

- 4

- 1K