Papermaker85 5,000+ posts

Banned

i dont see anything special about the woofer. the biggest variable in the voicecoil is the bonding agent that has to isolate and bond each winding of the coil. as far as i know DD has the highest operating temp o there coils while most companys dont even back there coils DD bakes them twice.the ceramic based bonding agents nasa use have a much high opt tem but are way heavier have way more expansion and high conductivity.. while most companies have excellent glues you have to take the time to properly cure the substance. ive never been impressed with any of the T2/t3 power woofers from RF. the team RF woofers where decent but that wasn't RF.. lolsean is a character. leave it at that

well, lets not stray from what you said. you didn't say there wasn't anything new tech wise, you said it has nothing really going for it.

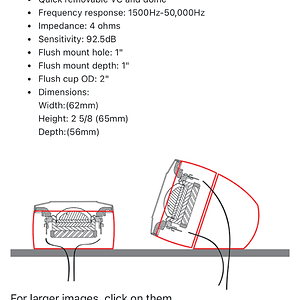

starting with the topology of the motor, that's not a standard arrangement in which the flux path has one loop equating to one gap, this has 2. I call it a floating gap. the bottom gap is apposed to the top and the coils run in a push/pull formation. when one coil winding leaves one gap and begins to enter another, a breaking occurs by the opposed flux path being opposite polarity of the originated gap thus keeping it from over travel and mechanical damage. not that I see that happening anyways considering the spider diameter is larger then the standard 8" and 10" (there 12" due to the 5" coil with very healthy progressive roll)

the coil its self surpasses round wound or flat wound via edge wound method. this is more efficient when it comes to maximum coil density without causing excess air pockets between layers and increase inductance from the layers interaction with the core.

the coil is also ceramic toughened with a thicker then standard coil former. this helps with heat and structural integrity.

the coil is single 1 ohm (there wired internally together) yet theres two sets of leads. this is common SQ practice to keep the stresses and weights even on the spider. it costs more to do but pays off in the klippel testing.

the frame acts as a heat sink as does the above and below gaps structures. they also reduce modulation.

the cone is more or less a rohacell copy. very strong yet very light. this helps with accurate tonal reproduction under high excursion.

and the 19" portion, that helps make it a true 18" cone in terms of area. not perfect but helps. im sure it was also done for proprietary reasons for recone prevention outside of Rockford. id rebuild it with an adapter my self

as far as the push pull when your have an inductive load your going to have lag/lead the push pull configuration wont help lower inductance and feedback or increase motor strength.