- Thread Starter

- #16

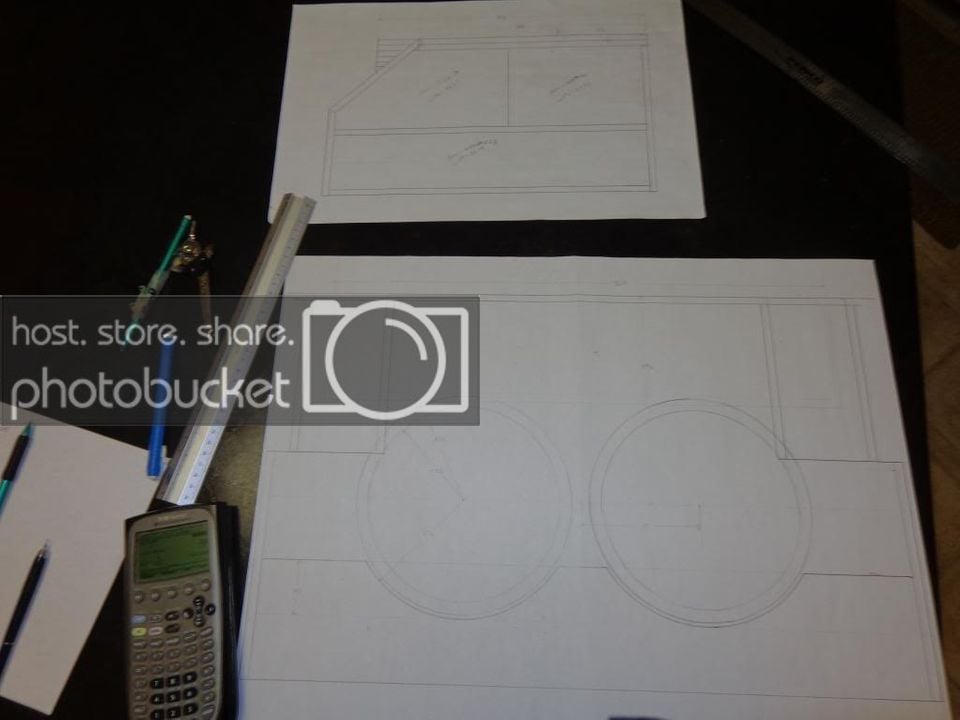

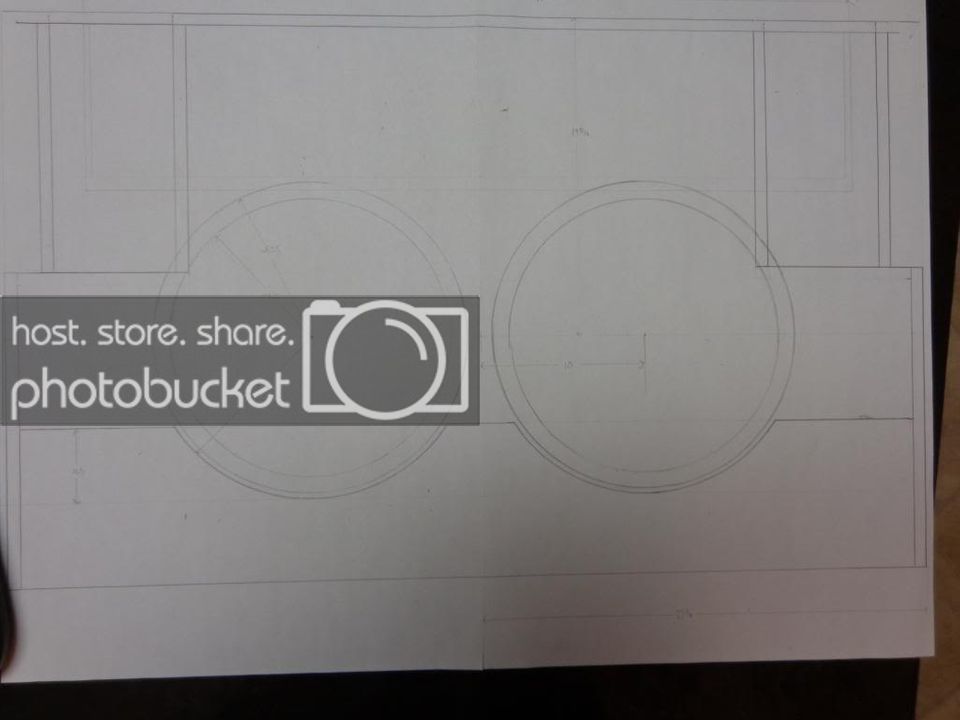

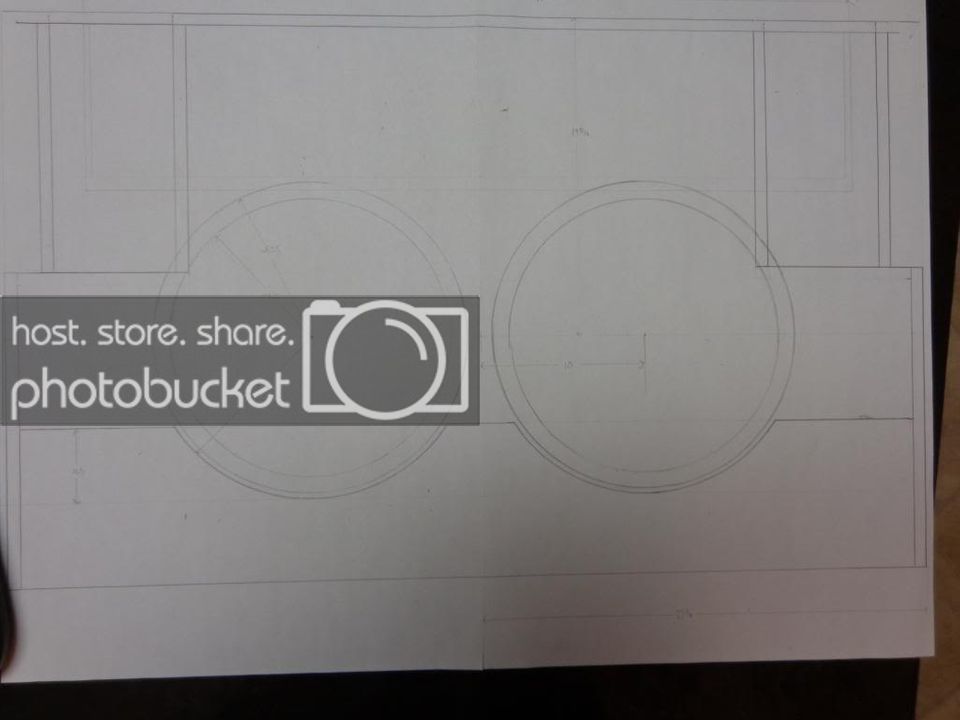

Back to work. This evening much of the design was finalized- the big uncertainty beforehand was sub placement on the top of the box. I got to use some calculus on tonight's design work too! There are small details to still figure out, such as bracing and a spot for the bus bars- this stuff I've mostly got planned out in my head.

I would have liked the subs to be farther apart for better cosmetic appeal- but the battery boxes restrained this. Everything is a trade off in the design; a delicate balance between performance and cosmetics. When it comes to sacrifices, performance has priority. Any experienced shop can make things look pretty.

Over the next few days much work is still required in order to meet our Thursday deadline. Tomorrow will be a 14 hour day.

I would have liked the subs to be farther apart for better cosmetic appeal- but the battery boxes restrained this. Everything is a trade off in the design; a delicate balance between performance and cosmetics. When it comes to sacrifices, performance has priority. Any experienced shop can make things look pretty.

Over the next few days much work is still required in order to meet our Thursday deadline. Tomorrow will be a 14 hour day.