Hello all,

I have returned here to A) vent a little bit B) Showcase the absurdity in my car audio purchases thus far, especially the latest: Soundqubed with a big (and surprising) fail.

1) Bought a BOSS amp, discovered it only puts out less than half of stated RMS, returned after being enlighted by you all. Thank you.

2) Bought an enclosure that read ''1.5 cubes @ 34hz", told you guys here on the forum, y'all pointed out that it was likely only 0.7 cubes. Still waiting for the shipment so I can resell it at a loss on Craigslist or Offer-up. Burn.

3) Received shipment from Soundqubed Today. One 10'' 600 rms dvc sub. One S1-850 mono amp. Great sub reviews from people who ran the sub hard for months, maybe years for one particular review, & great amp dyno results on youtube. Sweet, right? Not so fast...

Sub packaging: NO padding or protection on top (cone), and NO padding or protection on the bottom (magnet). I pick up the package and wonder why it feels so saggy, look underneath and there is a gaping hole in the bottom of the box, the

magnet is poking through, exposed to the great outdoors. What - the - faaack. Handed the box back to the FedEx guy and signed the refuse-to-accept form.

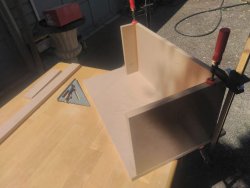

Amp packaging: paper padding on only 2 of the 4 sides (D+ for effort?), no padding or protection on the bottom of the package. Thin amp box (retail box with logos/imagery) to cardboard, that's it. No visual signs of damage, but considering the entire bottom of the amp had no reasonable protection from the handling during shipping, internal electronics

could have taken some beatings.. maybe leading to premature amp failure at some point? I'd really like to know what you guys think about this one. Would you return the amp too? I'm pretty darned sure i'm going to.

This is from the 'returns' section on their website, LOL:

SERVICE RETURNS:

- Create an RMA.

- ****Pack the items(s) well to prevent damage during shipping****.

- Ship item(s) to us at the address above at your expense.

There seems to be a number of satisfied Soundqubed customers out there, so I'll speculate that they had a new employee in the shipping department, a ding-dong at that.

Every damn time it's something. Why me, oh why. Thanks for listening