americannight 10+ year member

Senior VIP Member

- Thread Starter

- #61

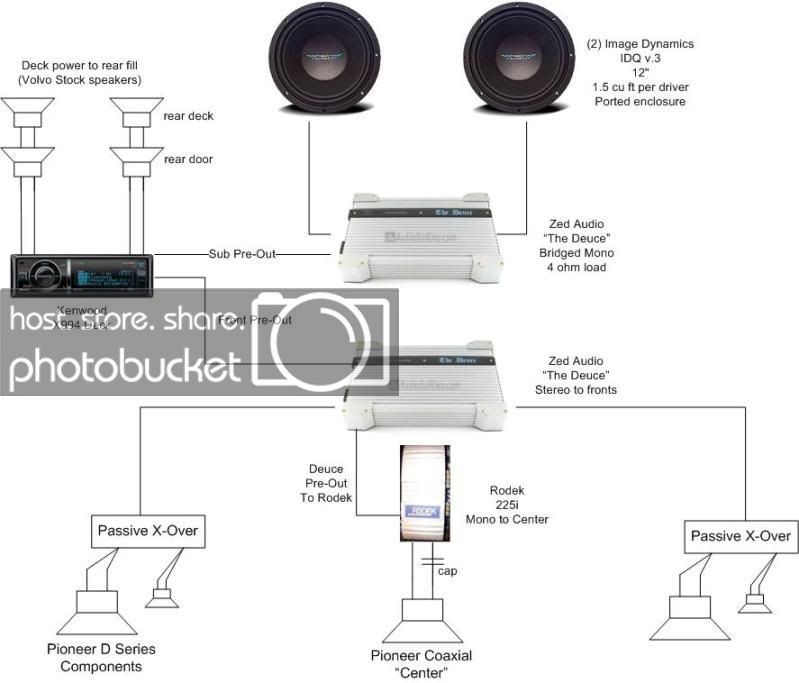

Tonight I put a couple hours into the system, getting ready for the subs build coming up. I removed the rear deck speakers and deadened the top side of the rear deck. The bottom of the rear deck already got a layer of GTMatt. So now I have a layer of deadener on both sides. The rear deck speakers were surprisingly large in this car, look like 8" woofers with a coaxial mounted tweeter. Not a bad rear deck opening if someone wanted to go for a free air mounted 8" woofer in this vehicle. That would definitely be a more straight forward build than what I am doing here. For me, I have removed the rear deck speakers and will leave the holes open for the bass to pass through. I'm getting accustomed to these fronts now and can't wait to have the subs in action. Over the weekend I hope to have a rough cubic footage measurement of the airspace I have to dedicate to the subs and then will email Frankie at ID to get some specifics on how large to make the port. I'm shooting for a 35Hz tuning. We'll see how that works out with the amount of air space I have to sacrifice. I'm estimating somewhere between 1.5cu ft. and 2.0 cu ft. per IDQv3 12 driver. Deuce bridged mono into 4 ohms should really put out a nice amount of power for the bass. At least according to Steve Mantz, the Deuce does better on the bench into 4 ohms than the original hifonics zeuss. Can't wait to experience this bass.

Here's before the GTMatt applied to the rear deck.

Here's after. I applied more of the mat towards the middle, most flexible, parts of the rear deck. I have a feeling I may need to add more deadening to the rear deck platform which sits over this metal. It will likely resonate quite a bit with what I am putting into this car.

Here's before the GTMatt applied to the rear deck.

Here's after. I applied more of the mat towards the middle, most flexible, parts of the rear deck. I have a feeling I may need to add more deadening to the rear deck platform which sits over this metal. It will likely resonate quite a bit with what I am putting into this car.