BerniniCaCO3 10+ year member

Junior Member

Hi!

This was my father's old stereo, and I've had it for 4 years.

Two nights ago it broke. I'd like to give a shot at repairing it myself, if I could get a little push in the right direction (or: also an answer like, it's not worth it/ parts can't be found so you should throw it out is also a valid response).

The faceplate still lights up and displays correctly.

There's no sound but that was an earlier and likely wholly unrelated issue.

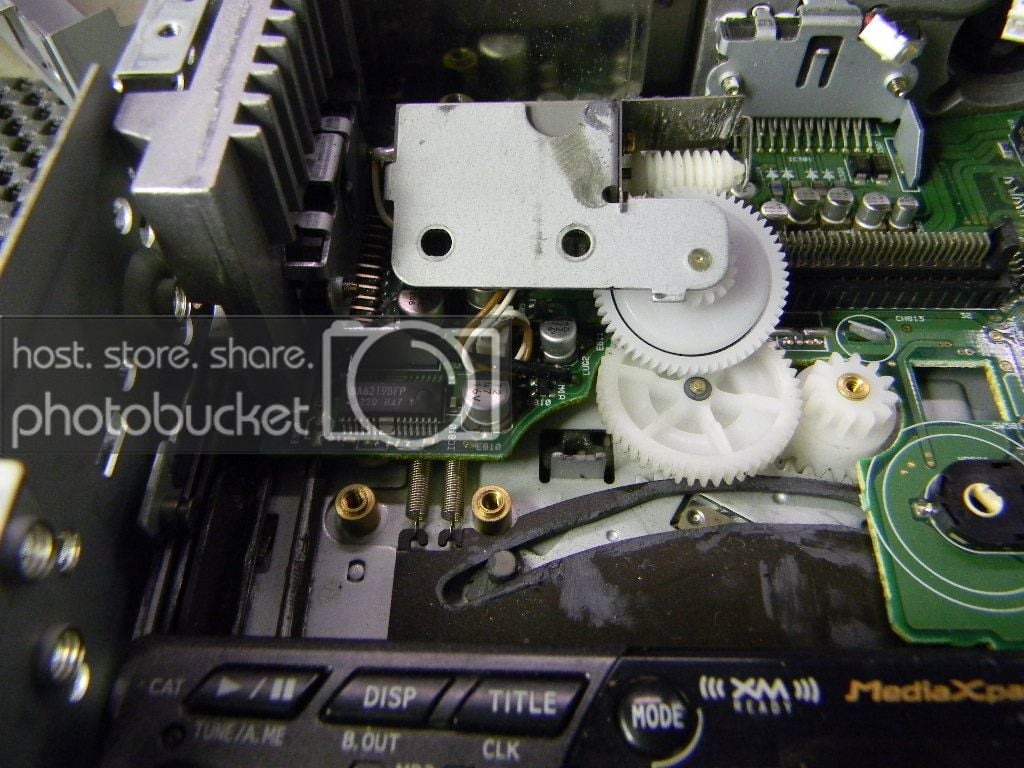

This radio has the 'phantom faceplate' which hides itself.

Two nights ago it came out on key-on position, opening flat, but never rose into the vertical position.

Then on key-off, it tries to raise up a little bit then fails to pull itself in (having just jammed itself).

It's stuck hanging out, flat.

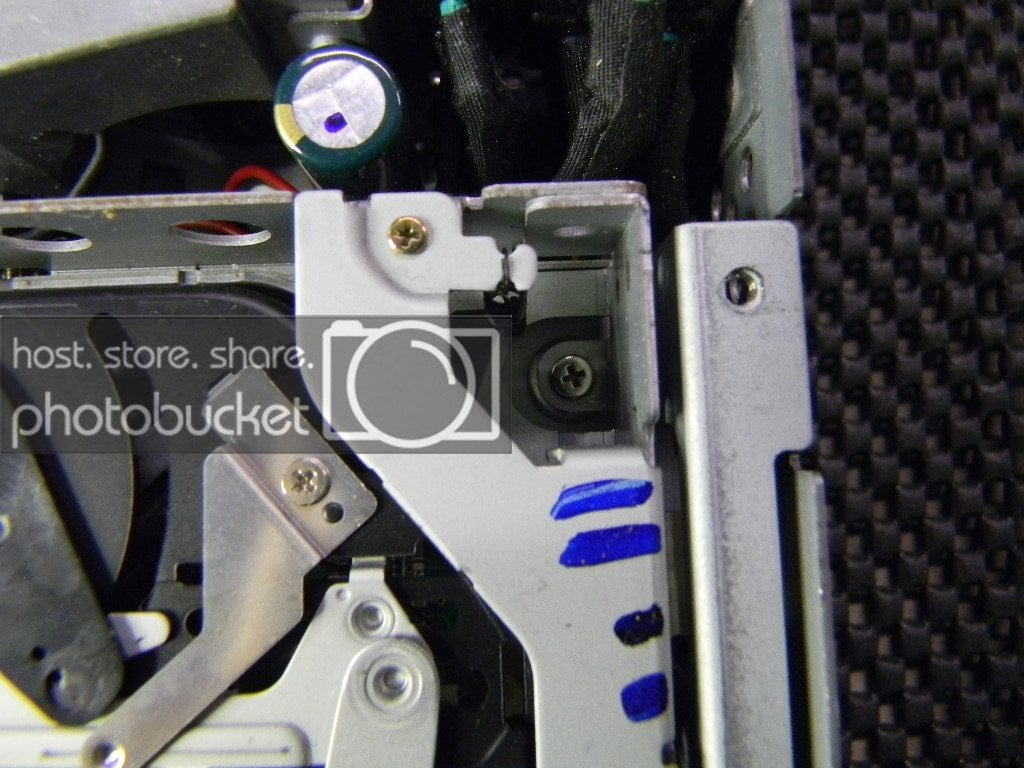

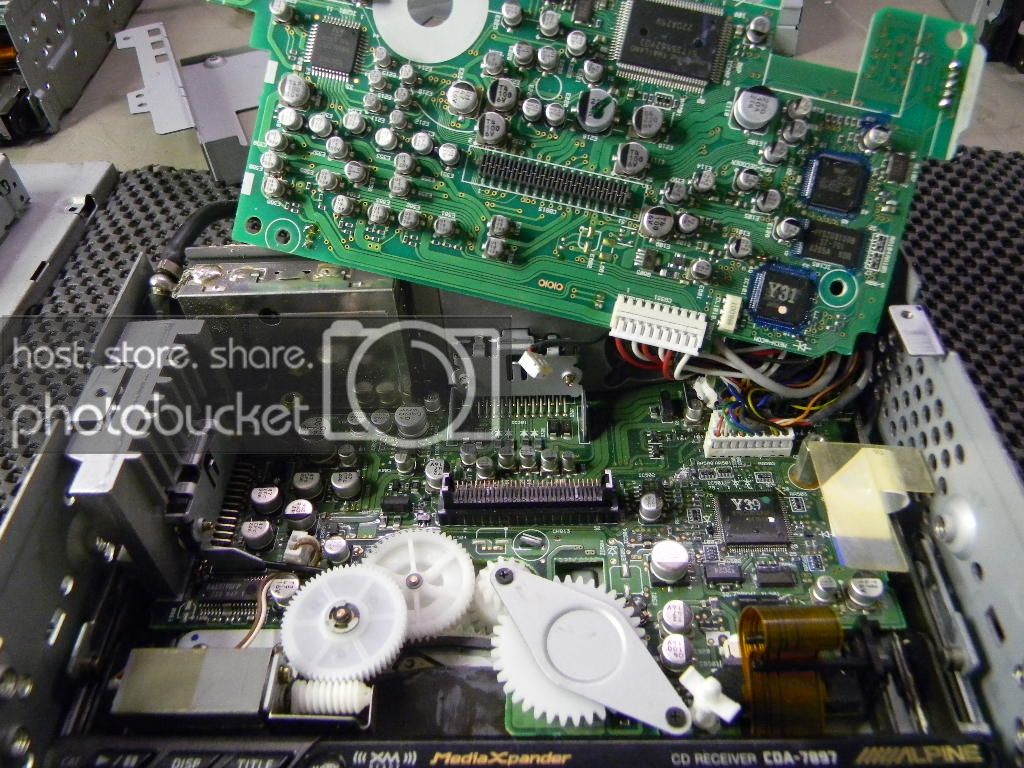

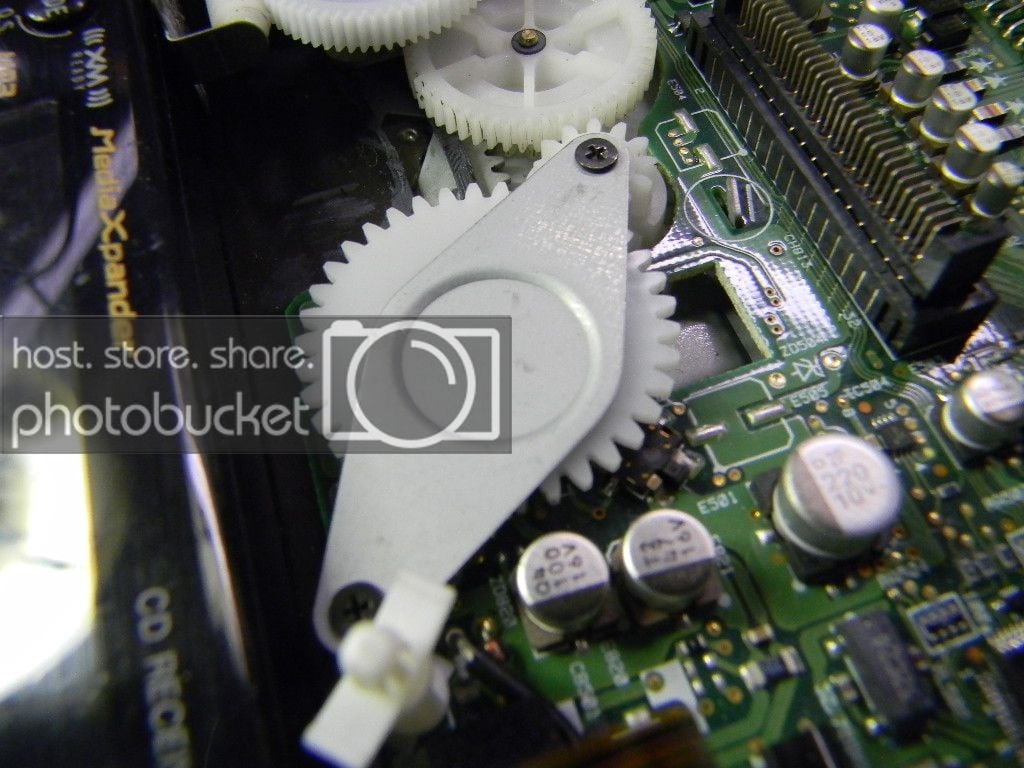

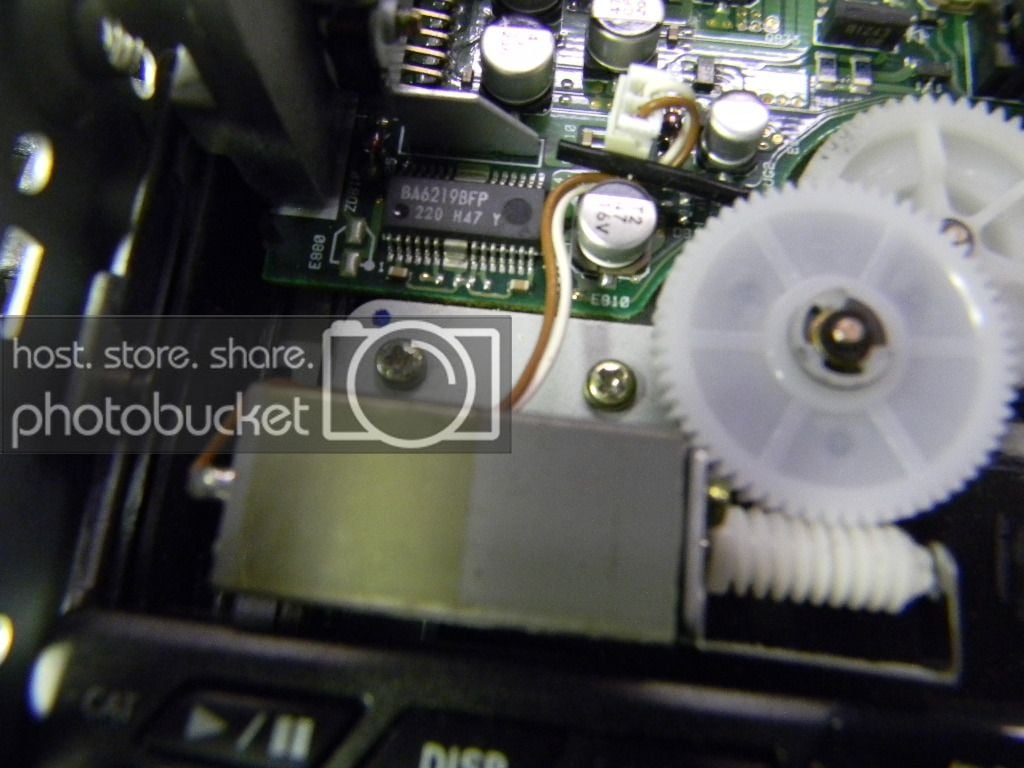

What am I looking at? A position sensor confused about where the faceplate should be, or just a little motor gone dead? Maybe a teflon gear worn smooth?

I'm handy, but I've never been inside stereo units before.

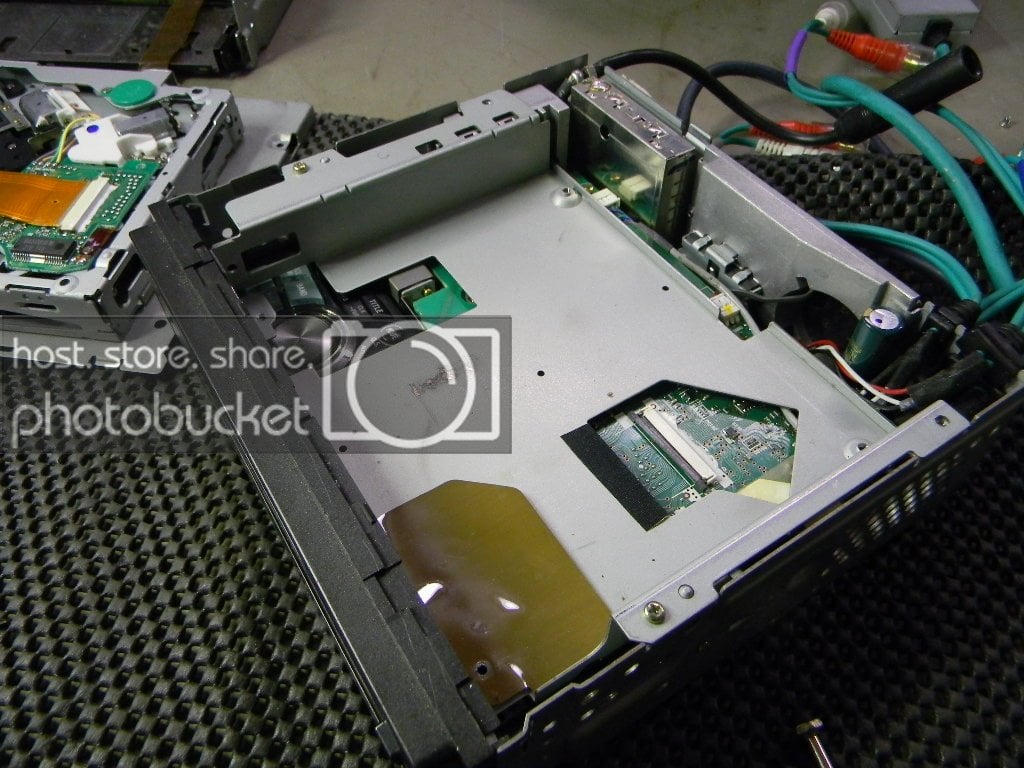

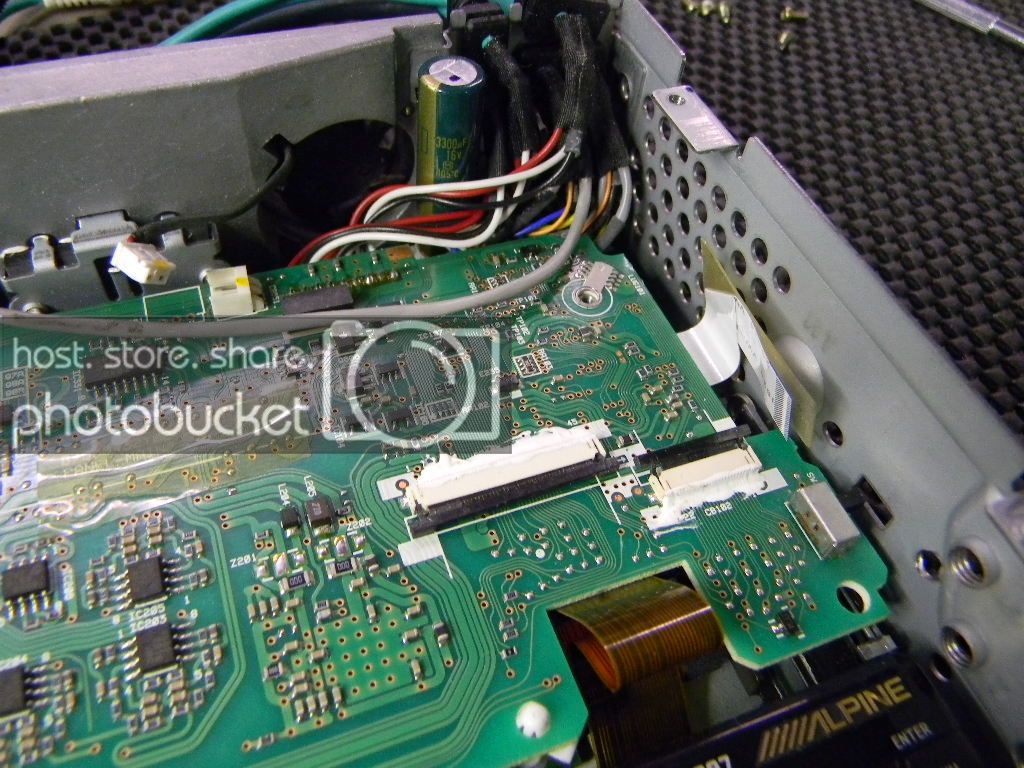

Wondering if I should attempt this/ if parts are still around/ and if once I have it open, maybe someone here has experience with the cda-7897 and can help me diagnose it with some detailed description and a photo of the insides.

I understand that I can repair it with alpine for $105+shipping. I don't have that money, not really (would be getting a $40 replacement if I had to...), so I'd like to fix this personally.

thanks in advance!

-Bernard

This was my father's old stereo, and I've had it for 4 years.

Two nights ago it broke. I'd like to give a shot at repairing it myself, if I could get a little push in the right direction (or: also an answer like, it's not worth it/ parts can't be found so you should throw it out is also a valid response).

The faceplate still lights up and displays correctly.

There's no sound but that was an earlier and likely wholly unrelated issue.

This radio has the 'phantom faceplate' which hides itself.

Two nights ago it came out on key-on position, opening flat, but never rose into the vertical position.

Then on key-off, it tries to raise up a little bit then fails to pull itself in (having just jammed itself).

It's stuck hanging out, flat.

What am I looking at? A position sensor confused about where the faceplate should be, or just a little motor gone dead? Maybe a teflon gear worn smooth?

I'm handy, but I've never been inside stereo units before.

Wondering if I should attempt this/ if parts are still around/ and if once I have it open, maybe someone here has experience with the cda-7897 and can help me diagnose it with some detailed description and a photo of the insides.

I understand that I can repair it with alpine for $105+shipping. I don't have that money, not really (would be getting a $40 replacement if I had to...), so I'd like to fix this personally.

thanks in advance!

-Bernard