keep_hope_alive Premium Member

Acoustics Engineer

I figured I should share the work I do with the forum, since I'm giving everyone advice and guidance.

This is a co-workers 2005 Sction tC. He is a recording engineer/musician/and sound tech and also works as an Acoustician with me.

I convinced him to upgrade his sound system and have a rolling reference system.

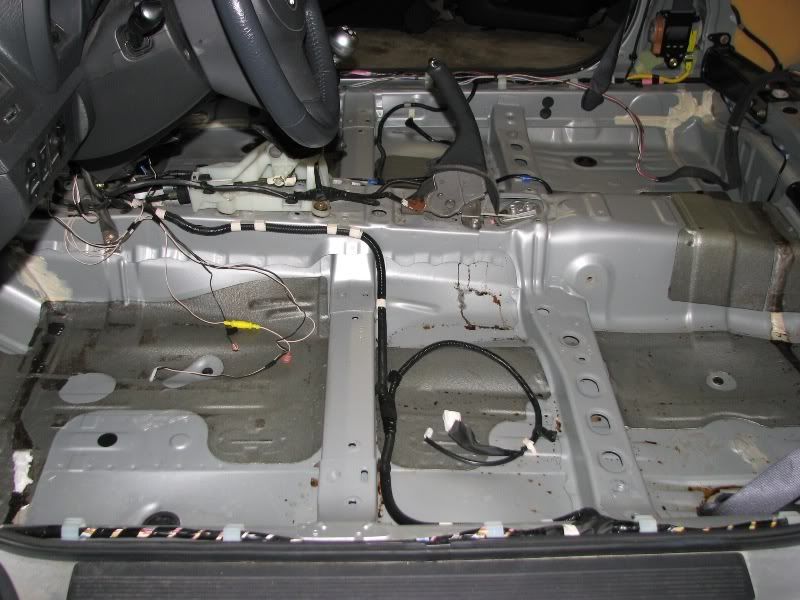

I am doing this build on weekends. Every time we finish for the day, he required that there was functionality. I am leaving out a lot of intermediate steps.

Equipment list is as follows:

Head Unit: Pioneer DEH-980BT

Front Speakers: Hertz Mille MLK-165 has a ML165 6.5" + ML28 tweeter

Rear Speakers: Hertz Mille ML2500 10"

Amp: Audison LRx 5.1k

Power Wire: Streetwires 1/0 amp kit

Speaker Wire: Tsunami 12awg

Interconnects: Monster Cable 6-channel

This list of equipment is all purchased authorized from a local shop. Owner didn't want anything used. Their prices are the same as online and they warranty directly. Cost of equipment listed is about $4000.

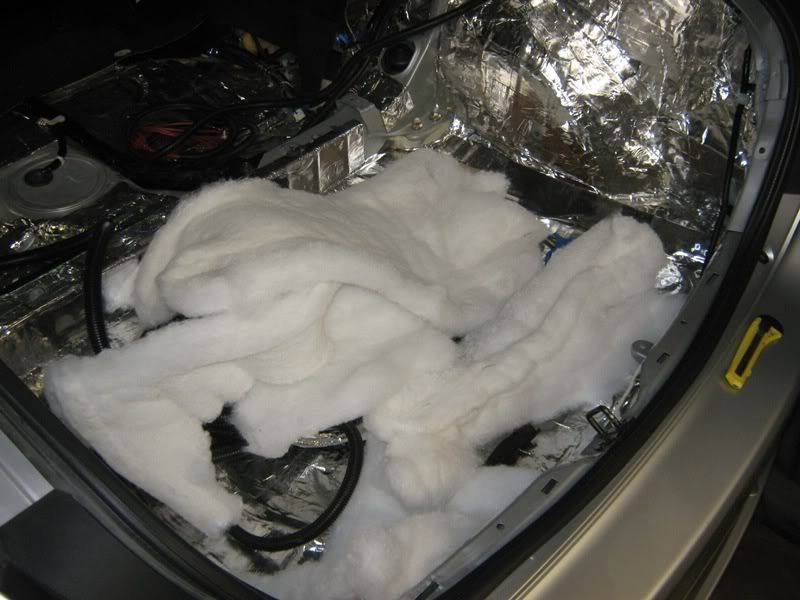

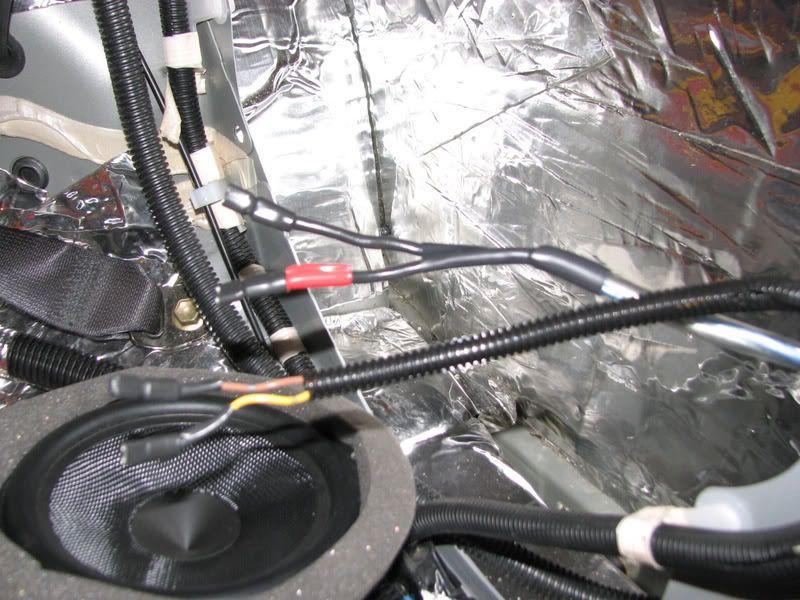

We also picked up 200st. ft. of Raammat BXT II and 200 sq. ft. of adhesive Ensolite ($800 total). The entire vehicle will be treated.

Then we bought lots of install accessories - wire, parts, resin, fiberglass, MDF, and our total is over $7000.

On to the pictures...

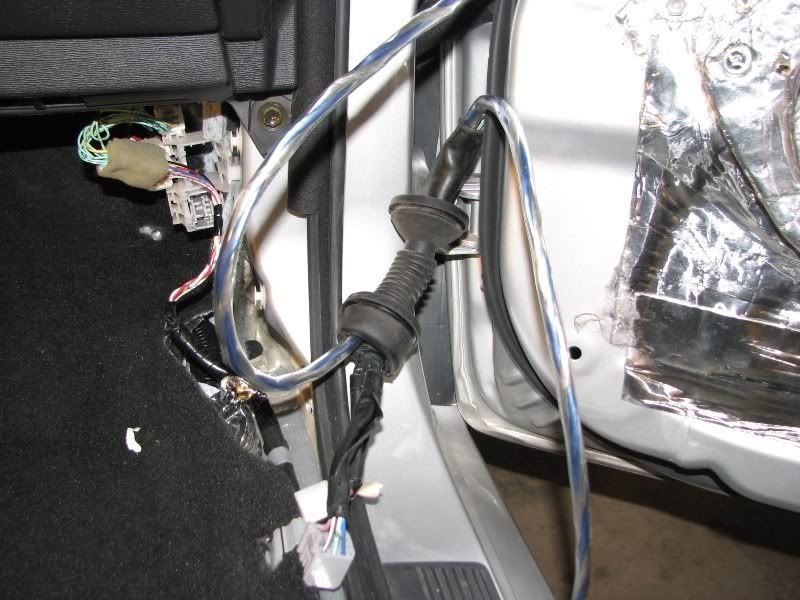

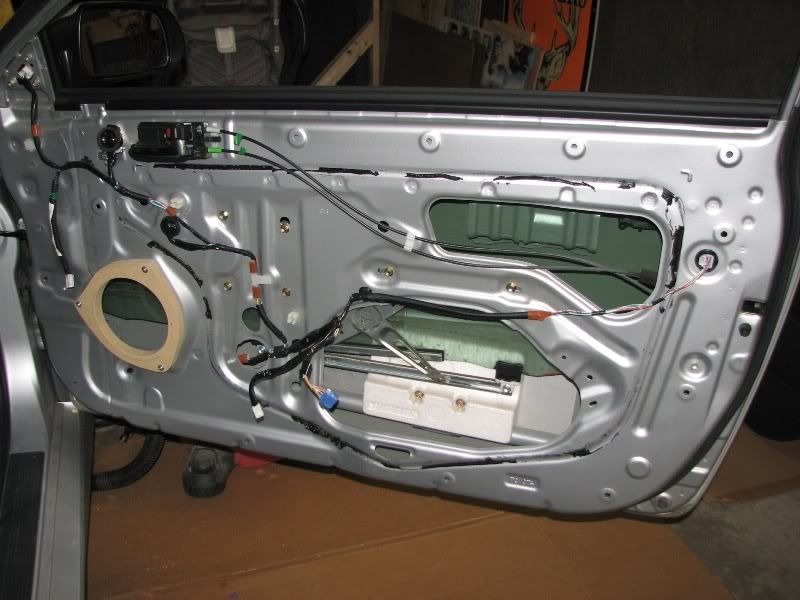

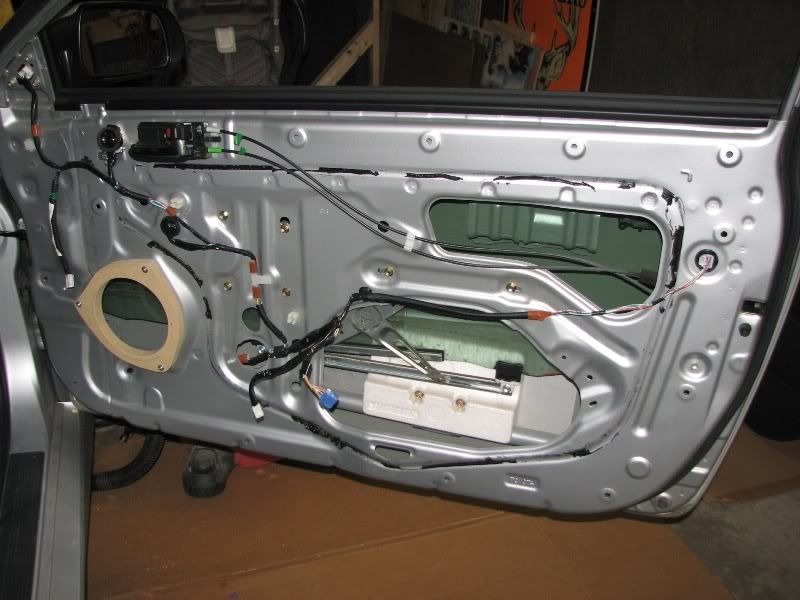

Factory Door - remove panel, remove all wiring clips, remove factory speaker, and clean all metal surfaces

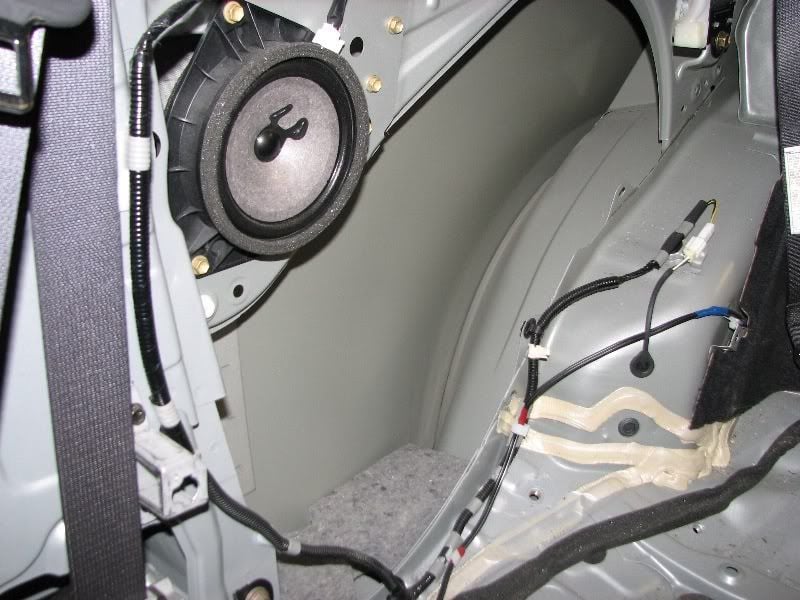

Trace the factory speakers and make a new baffle out of 3/4" MDF

Mount using the factory speaker rivet holes and a 1.5" 10-24 machine screw and bolt.

Test fit before deadening

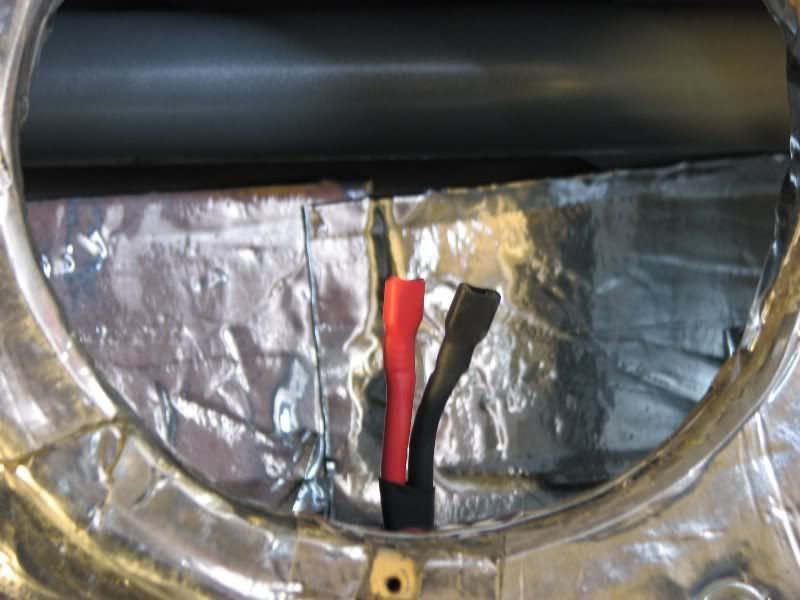

You can't let MDF get wet - deaden the baffle

Cover it 100%

but don't cover the mounting holes! //content.invisioncic.com/y282845/emoticons/smile.gif.1ebc41e1811405b213edfc4622c41e27.gif

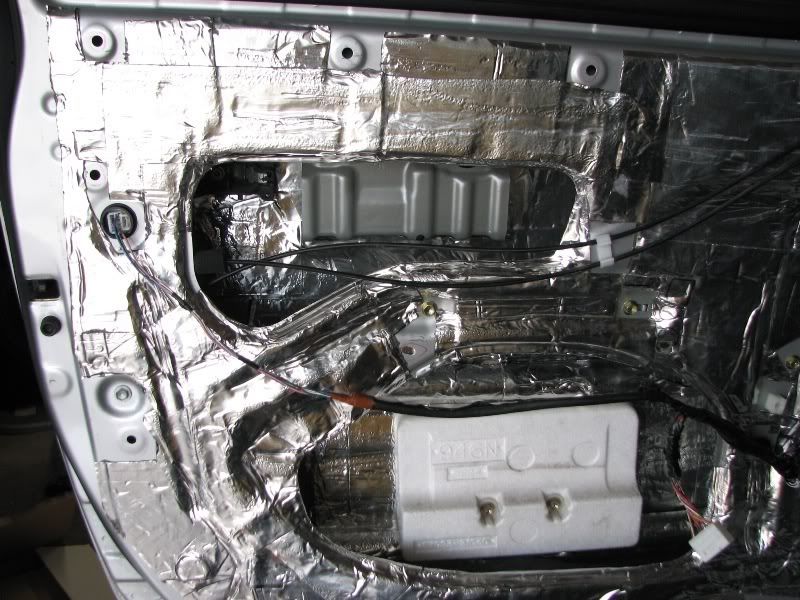

you must protect the speaker from rain water. i use 3/4" closed cell foam weatherstripping along the top of the inside of the opening. gives the water a channel to follow AROUND the speaker.

then deaden the seam between the baffle and the door and over the foam

This is a co-workers 2005 Sction tC. He is a recording engineer/musician/and sound tech and also works as an Acoustician with me.

I convinced him to upgrade his sound system and have a rolling reference system.

I am doing this build on weekends. Every time we finish for the day, he required that there was functionality. I am leaving out a lot of intermediate steps.

Equipment list is as follows:

Head Unit: Pioneer DEH-980BT

Front Speakers: Hertz Mille MLK-165 has a ML165 6.5" + ML28 tweeter

Rear Speakers: Hertz Mille ML2500 10"

Amp: Audison LRx 5.1k

Power Wire: Streetwires 1/0 amp kit

Speaker Wire: Tsunami 12awg

Interconnects: Monster Cable 6-channel

This list of equipment is all purchased authorized from a local shop. Owner didn't want anything used. Their prices are the same as online and they warranty directly. Cost of equipment listed is about $4000.

We also picked up 200st. ft. of Raammat BXT II and 200 sq. ft. of adhesive Ensolite ($800 total). The entire vehicle will be treated.

Then we bought lots of install accessories - wire, parts, resin, fiberglass, MDF, and our total is over $7000.

On to the pictures...

Factory Door - remove panel, remove all wiring clips, remove factory speaker, and clean all metal surfaces

Trace the factory speakers and make a new baffle out of 3/4" MDF

Mount using the factory speaker rivet holes and a 1.5" 10-24 machine screw and bolt.

Test fit before deadening

You can't let MDF get wet - deaden the baffle

Cover it 100%

but don't cover the mounting holes! //content.invisioncic.com/y282845/emoticons/smile.gif.1ebc41e1811405b213edfc4622c41e27.gif

you must protect the speaker from rain water. i use 3/4" closed cell foam weatherstripping along the top of the inside of the opening. gives the water a channel to follow AROUND the speaker.

then deaden the seam between the baffle and the door and over the foam