mrclean636

10+ year member

Time is Money

I was made aware of this article today, it is from DD's June Newsletter. Figured I would share, it is informative.

**I TAKE NO CREDIT FOR THE INFORMATION IN THIS ARTICLE, I DID NOT WRITE IT //content.invisioncic.com/y282845/emoticons/smile.gif.1ebc41e1811405b213edfc4622c41e27.gif **

"

What makes a DD coil different?

DD takes pride in not cutting any corners when it comes to the parts used in our subs, and our voice coils are one of those parts. We source our coils from the world’s leading voice coil manufacturer. Then we have them custom wind all of our coils to DD’s stringent specifications. With their combined features DD coils achieve the highest thermal ratings in the industry for every diameter of coil we use.

Most of our competition’s coils sustain severe thermal damage around 300-500 degrees Fahrenheit. DD coils are able to handle temperatures above 700 degrees Fahrenheit. Our coils have several features that set them apart from lesser coils. We start by using thick gauge, double layer, anodized aluminum formers wrapped with Kapton, then nomex spunlace. The double layer aluminum acts as a heat sink to pull massive amounts of heat away from the wire and adhesives. Then we add heat dissipating radiators directly above the coil and at the top of the former to pull even more heat away from the coil and adhesives. The Kapton and Nomex layers add further strength to the coil former and insulate the adhesives from the high temperatures.

DD coils are then wound with the highest temperature wire and adhesives available. The extra lengths we go to in our design give our coils the highest level of durability and reliability possible. All of the subwoofers built in our facility have coils made with these same materials and techniques, from the 6.5” up to the new 21”. We don’t build to the good, better, best philosophy. Every speaker gets the best parts available.

Why are there so many coil options?

To continue our dedication to the custom installers out there, we offer more coil options than any sub manufacture in the world. In the 3500 and 9500 series subwoofers you can choose from eight different coil options. We have Copper D.5, D.7, D1, D1.5, D2, and D4, and Flat Wound Aluminum D1 and D1.5. Having this many coil options allows the installer extreme flexibility with subwoofer configurations and applications.

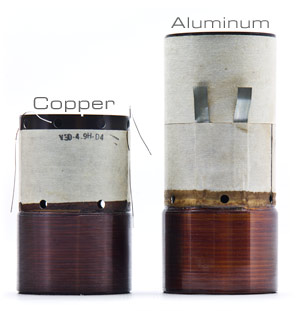

Copper vs. Aluminium:

Contrary to the way some other companies buy their products, our copper coils and aluminum coils have the same power handling, because they are all 100% American made with the same coatings and adhesives,. Other brands buy their speakers and parts from China and may offer an aluminum coil as an option. The aluminum coil is usually from the USA, and inherently has a higher temperature rating than the Chinese coil. They will tell you their aluminum coils have a higher power handling than copper, but they don’t tell you why. We ONLY use American coils, so we don’t have their power handling differences/ problems. The performance difference between copper and aluminum coil windings lies in the physical and resistance differences in the two materials. Copper is the more efficient conductor, able to transmit the same current with less cross section area. Aluminum requires more cross section area to do the same job. Aluminum has lower mass than copper giving the ability to move the same current, albeit through a larger conductor than copper, but with an overall reduction in mass.

The larger surface area of aluminum can have an advantage in a voice coil when it comes to the length of the coil windings. An aluminum coil of the same impedance as copper will end up with a longer winding length, increasing the Xmax number.

Some system designs may benefit from the longer Xmax if the system uses extremely long excursions, as may the case is competition vehicles making high distortion 2 second SPL runs. The longer coil windings keep more turns of wire in the magnet gap at high excursion... The aluminum wire, with its larger cross section area, is not as efficient as copper. A copper wire coil will pack more turns of wire into the magnet gap and results in higher energy over the operating Xmax of the coil. Well designed enclosures usually give better performance with the more efficient copper windings in both sound quality and output...

As we said earlier, the power handling differences between copper and aluminum are negligible IF both wires are using the same coatings and same adhesivev systems. Aluminum will have more surface area to dissipate heat, but takes more power to reach the higher efficiency of the copper coil, in subwoofer applications. In midrange/tweeter applications, the lighter aluminum wire can have significant impact on high frequency performance where moving mass dominates...

In 95% of the applications we see, the copper coils are the way to go...

"

**I TAKE NO CREDIT FOR THE INFORMATION IN THIS ARTICLE, I DID NOT WRITE IT //content.invisioncic.com/y282845/emoticons/smile.gif.1ebc41e1811405b213edfc4622c41e27.gif **

"

What makes a DD coil different?

DD takes pride in not cutting any corners when it comes to the parts used in our subs, and our voice coils are one of those parts. We source our coils from the world’s leading voice coil manufacturer. Then we have them custom wind all of our coils to DD’s stringent specifications. With their combined features DD coils achieve the highest thermal ratings in the industry for every diameter of coil we use.

Most of our competition’s coils sustain severe thermal damage around 300-500 degrees Fahrenheit. DD coils are able to handle temperatures above 700 degrees Fahrenheit. Our coils have several features that set them apart from lesser coils. We start by using thick gauge, double layer, anodized aluminum formers wrapped with Kapton, then nomex spunlace. The double layer aluminum acts as a heat sink to pull massive amounts of heat away from the wire and adhesives. Then we add heat dissipating radiators directly above the coil and at the top of the former to pull even more heat away from the coil and adhesives. The Kapton and Nomex layers add further strength to the coil former and insulate the adhesives from the high temperatures.

DD coils are then wound with the highest temperature wire and adhesives available. The extra lengths we go to in our design give our coils the highest level of durability and reliability possible. All of the subwoofers built in our facility have coils made with these same materials and techniques, from the 6.5” up to the new 21”. We don’t build to the good, better, best philosophy. Every speaker gets the best parts available.

Why are there so many coil options?

To continue our dedication to the custom installers out there, we offer more coil options than any sub manufacture in the world. In the 3500 and 9500 series subwoofers you can choose from eight different coil options. We have Copper D.5, D.7, D1, D1.5, D2, and D4, and Flat Wound Aluminum D1 and D1.5. Having this many coil options allows the installer extreme flexibility with subwoofer configurations and applications.

Copper vs. Aluminium:

Contrary to the way some other companies buy their products, our copper coils and aluminum coils have the same power handling, because they are all 100% American made with the same coatings and adhesives,. Other brands buy their speakers and parts from China and may offer an aluminum coil as an option. The aluminum coil is usually from the USA, and inherently has a higher temperature rating than the Chinese coil. They will tell you their aluminum coils have a higher power handling than copper, but they don’t tell you why. We ONLY use American coils, so we don’t have their power handling differences/ problems. The performance difference between copper and aluminum coil windings lies in the physical and resistance differences in the two materials. Copper is the more efficient conductor, able to transmit the same current with less cross section area. Aluminum requires more cross section area to do the same job. Aluminum has lower mass than copper giving the ability to move the same current, albeit through a larger conductor than copper, but with an overall reduction in mass.

The larger surface area of aluminum can have an advantage in a voice coil when it comes to the length of the coil windings. An aluminum coil of the same impedance as copper will end up with a longer winding length, increasing the Xmax number.

Some system designs may benefit from the longer Xmax if the system uses extremely long excursions, as may the case is competition vehicles making high distortion 2 second SPL runs. The longer coil windings keep more turns of wire in the magnet gap at high excursion... The aluminum wire, with its larger cross section area, is not as efficient as copper. A copper wire coil will pack more turns of wire into the magnet gap and results in higher energy over the operating Xmax of the coil. Well designed enclosures usually give better performance with the more efficient copper windings in both sound quality and output...

As we said earlier, the power handling differences between copper and aluminum are negligible IF both wires are using the same coatings and same adhesivev systems. Aluminum will have more surface area to dissipate heat, but takes more power to reach the higher efficiency of the copper coil, in subwoofer applications. In midrange/tweeter applications, the lighter aluminum wire can have significant impact on high frequency performance where moving mass dominates...

In 95% of the applications we see, the copper coils are the way to go...

"