Some of you may remember this install i previously did in a 2016 VW Golf R..

http://www.caraudio.com/forums/car-audio-build-logs-cars-trucks-suvs/634060-2016-volkswagen-golf-r-rebuild-audiofrog-brax-helix-illusion-audio.html

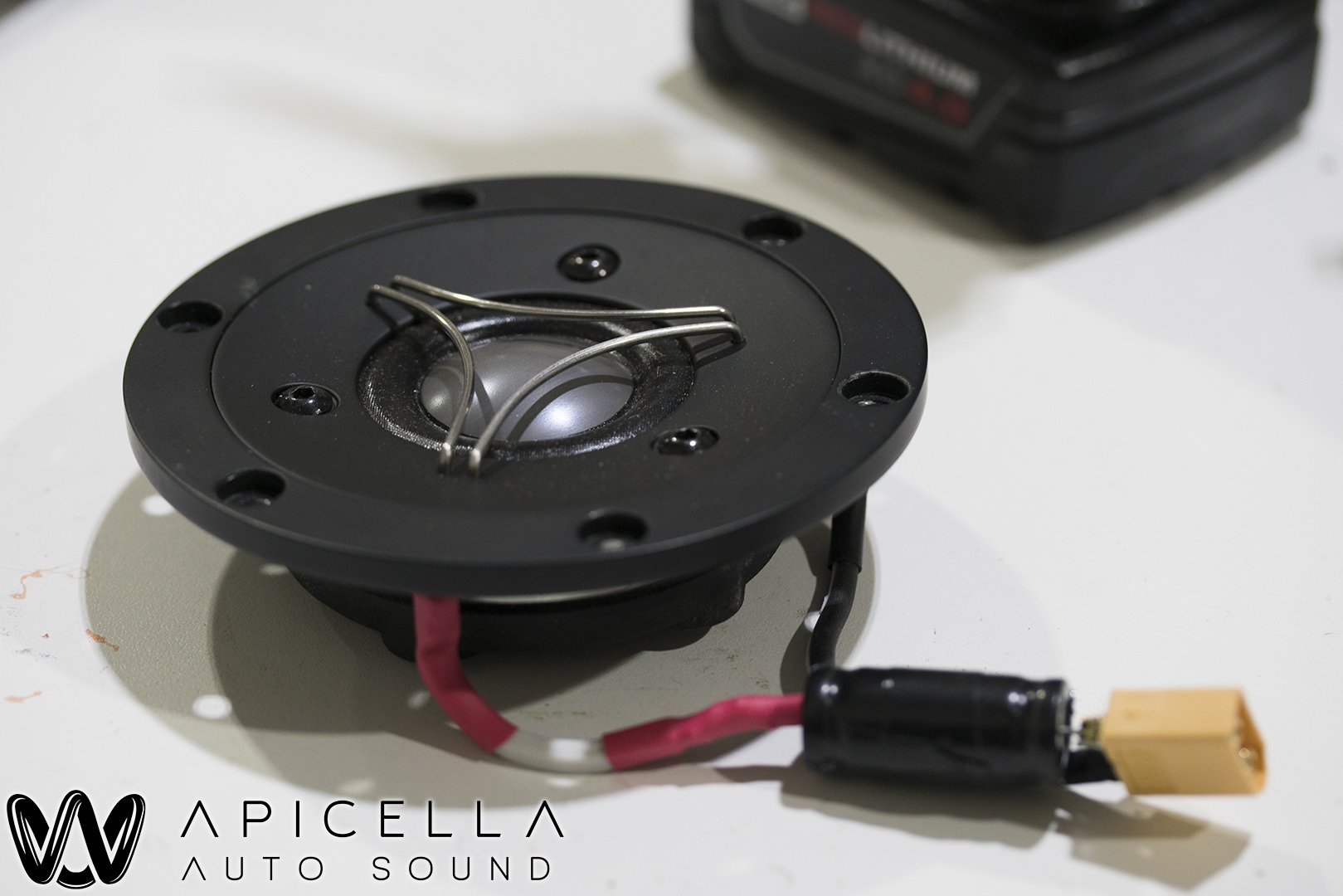

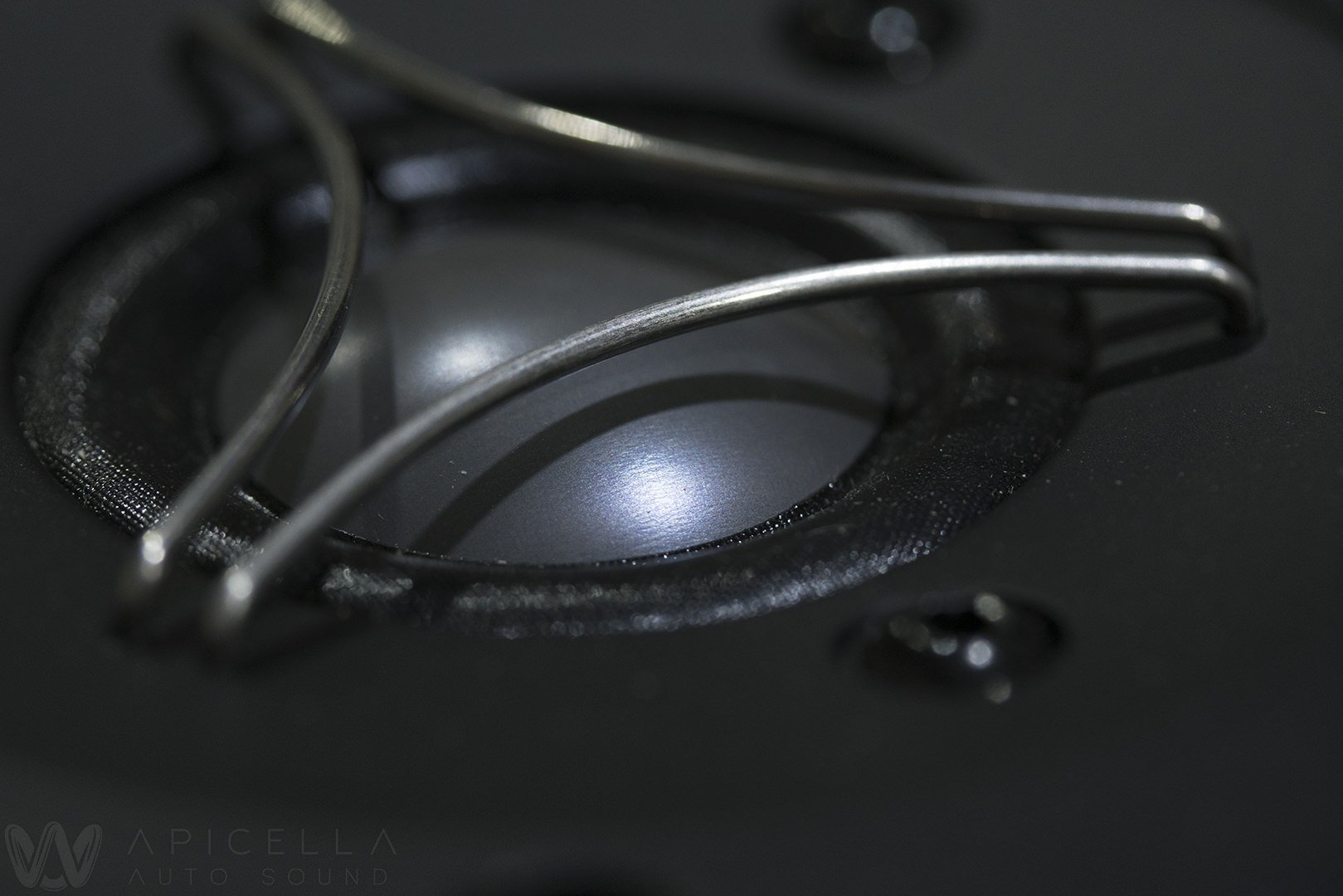

Well, like most car audio fanatics hes back for more upgrades. This time its a front stage rebuild, rear fill, and a Sony RSX-GS9 with an iPad mini. The front stage now consists of Audio Development W800NEO 8" midbass in custom kick panels, Scanspeak 12m midranges in the A-Pillars, and Satori TW29BN-B tweeters in the sail panels. Rear fill is using 2" Tang Band full ranges. All of this was to be installed with complete accurate reproduction of the signal in mind. What you wont see in this build log is the small 2 channel Arc Audio "micro" amplifier to power the rear fill, and the JL Audio Fix which fixes the oem sources signal and converts it to digital. The purpose of this is to well, give us a predictable signal so the same tune can be used between the Sony radio and the oem radio. It also gave us a digital out which was needed since you cant use the low level and high level inputs at the same time on the helix.

Side note, i apparently formatted my SD card on my camera or misplaced some photos before saving them to my computer somewhere during the kick panel, rear fill and a pillar build. Sorry :/

First things first was the kick panels. Some carpet was trimmed on both sides, and wires/plugs were moved on the driver side. These kicks were great as the car had these "cubbies" right behind where the kicks are, and where your feet would be, and had holes leading right into them. Because of this no crazy mods or ridiculously sized kicks were needed to get plenty of airspace.

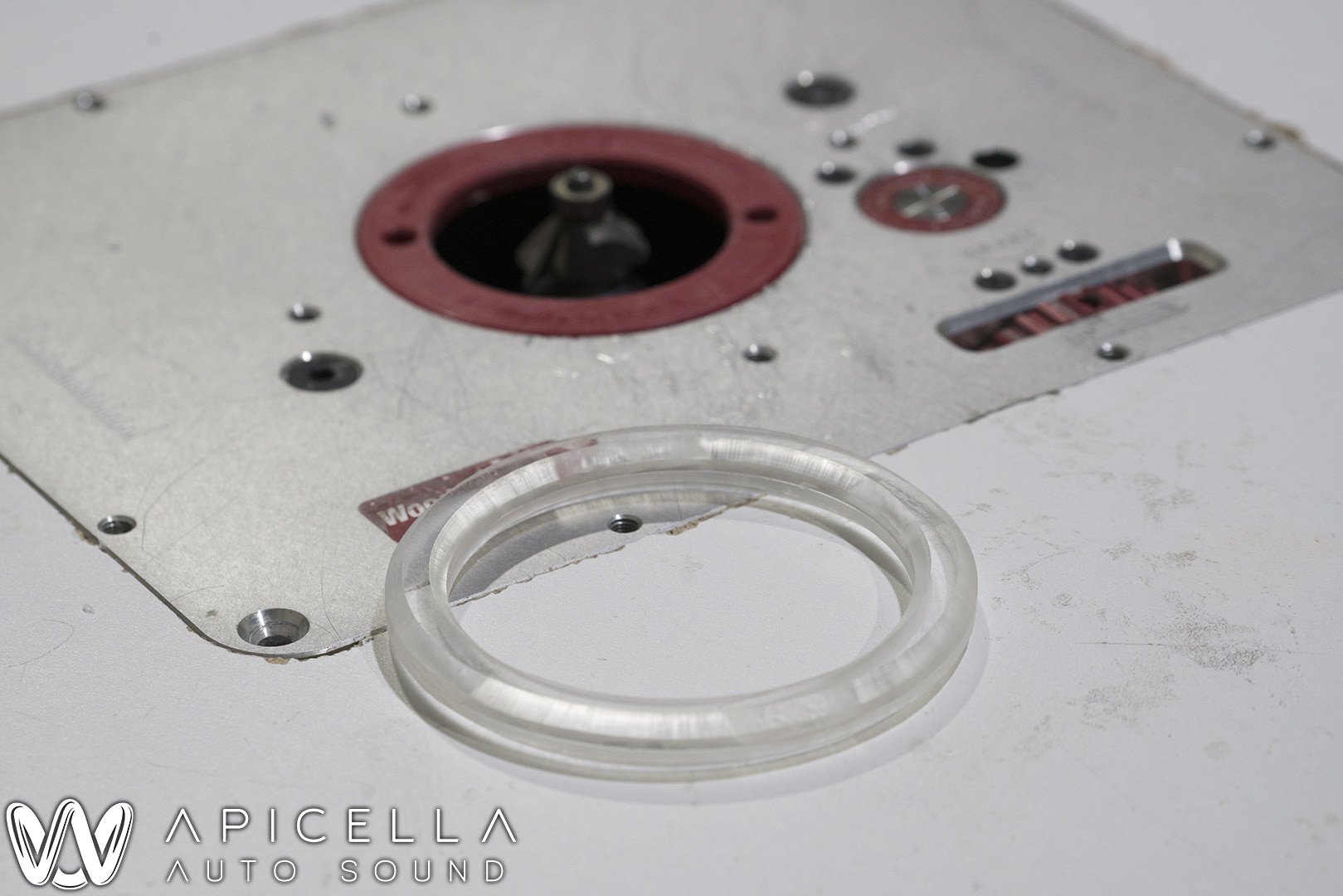

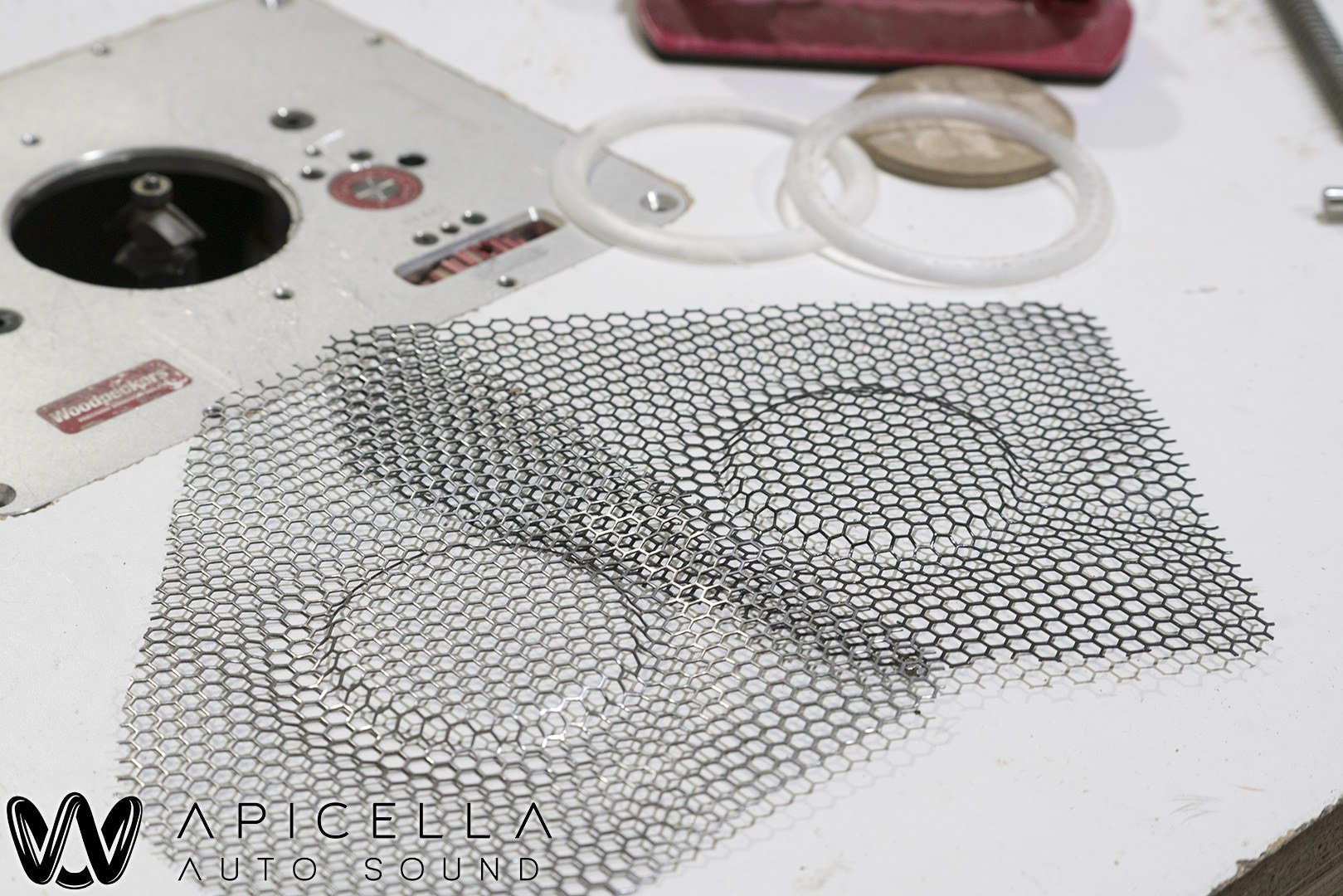

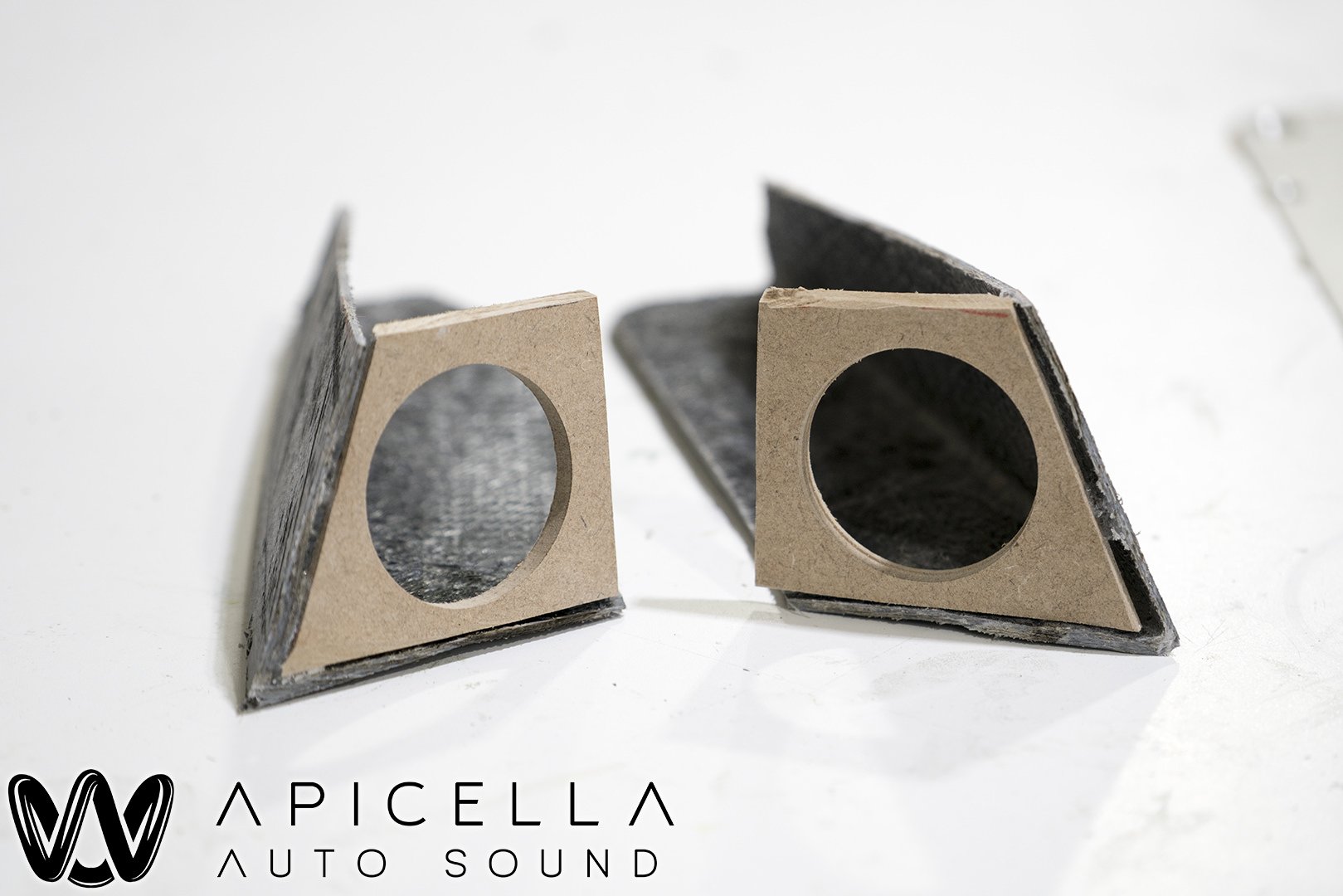

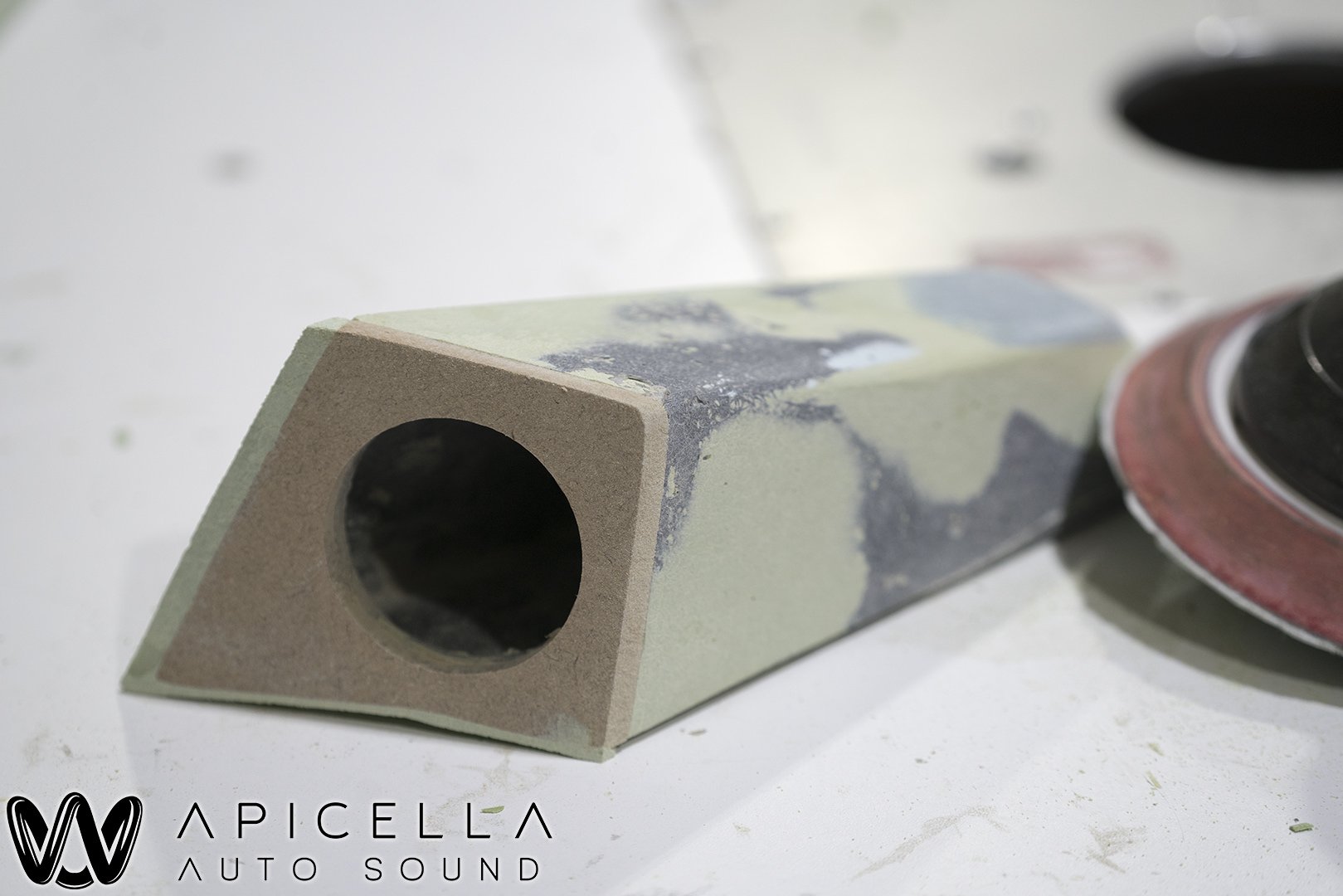

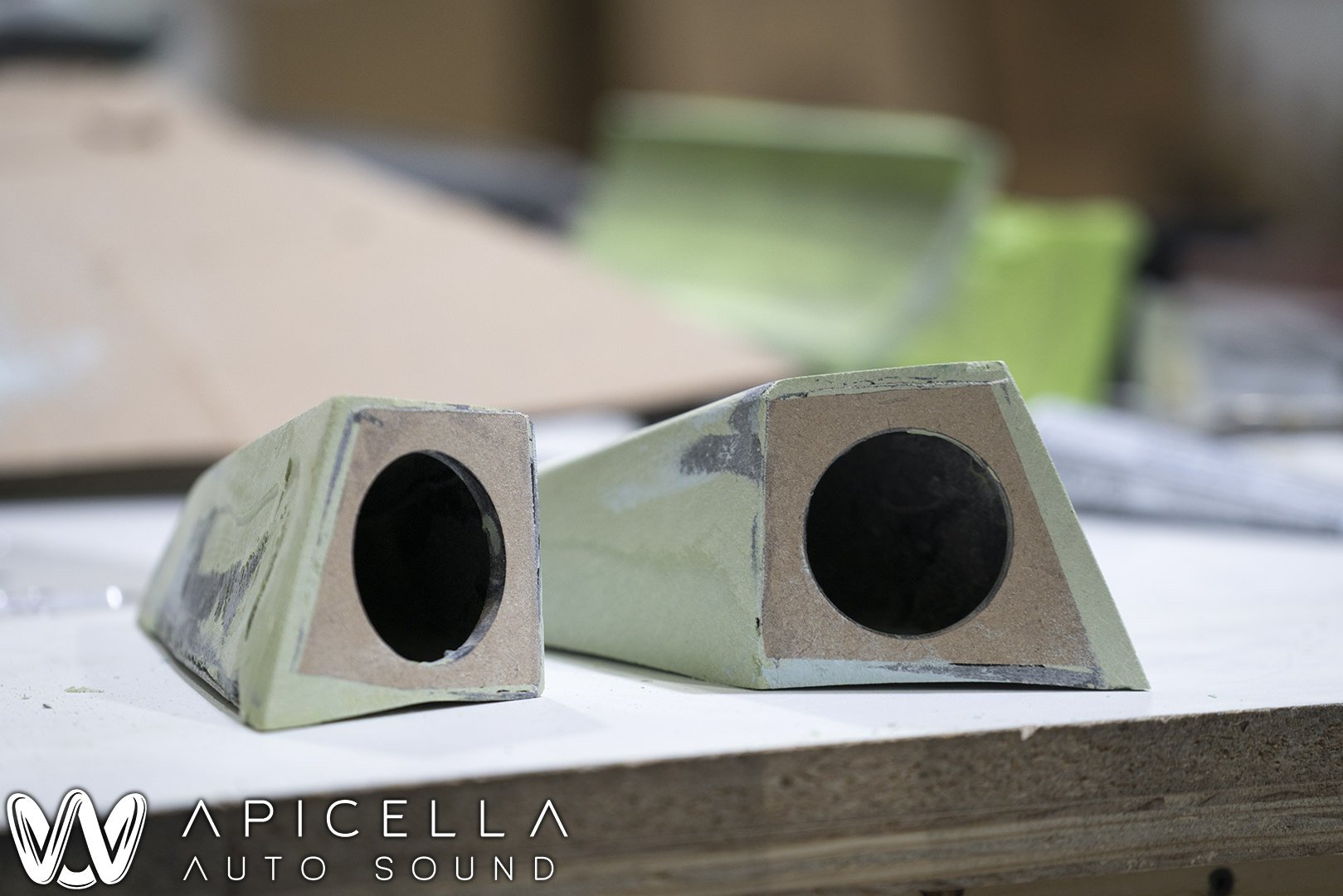

Like i said, i lost a lot of pics from the first few things in this build. Molds were made, baffles were cut and attached, kicks were glassed to withstand a nuke, and grills and their housings were made and attached. Here is the inner part of the grill being filled to assure a tight fit with no inconsistencies. After that the grill inserts were rabbeted to flush mount some steel grill to protect the drivers from wandering feet.

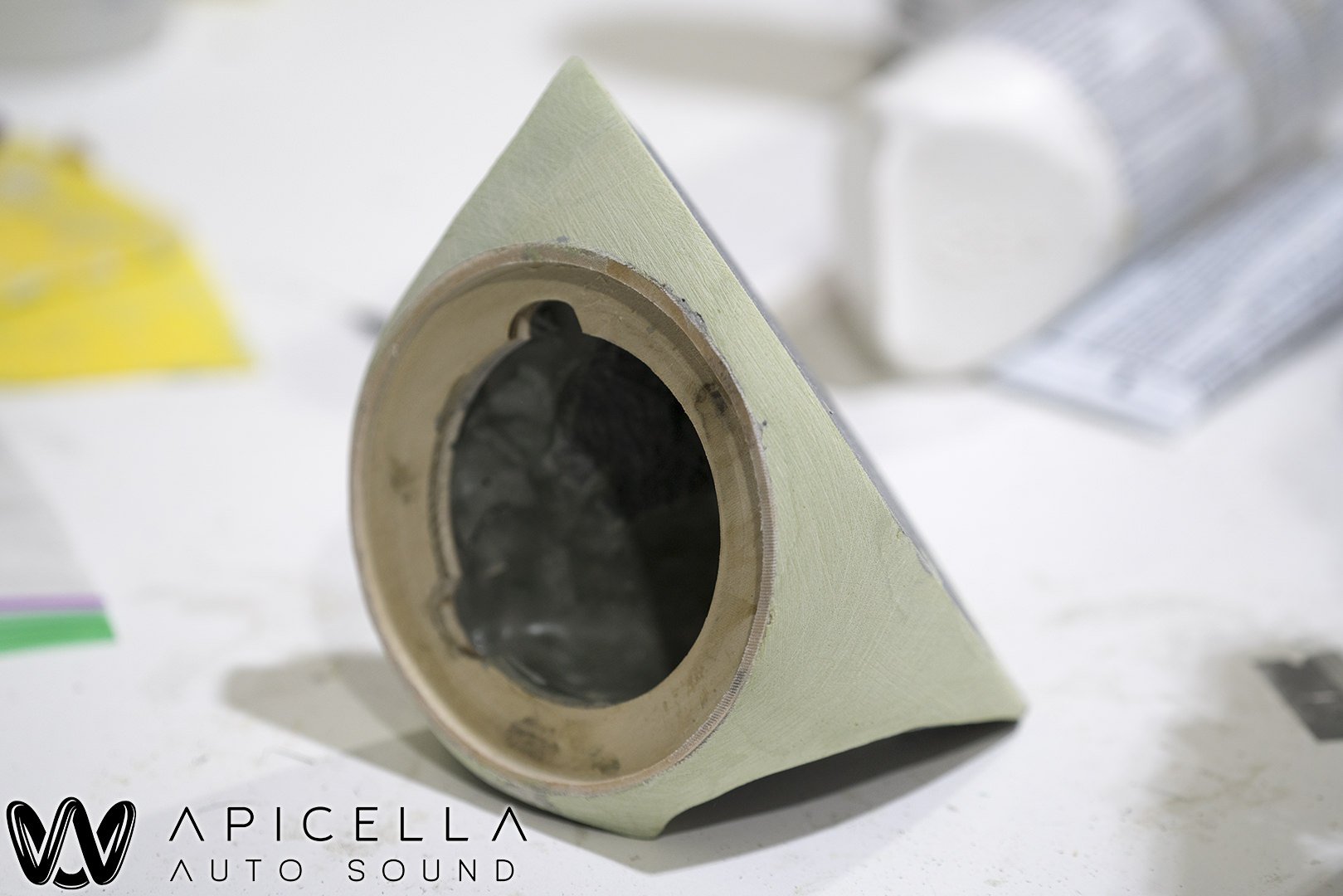

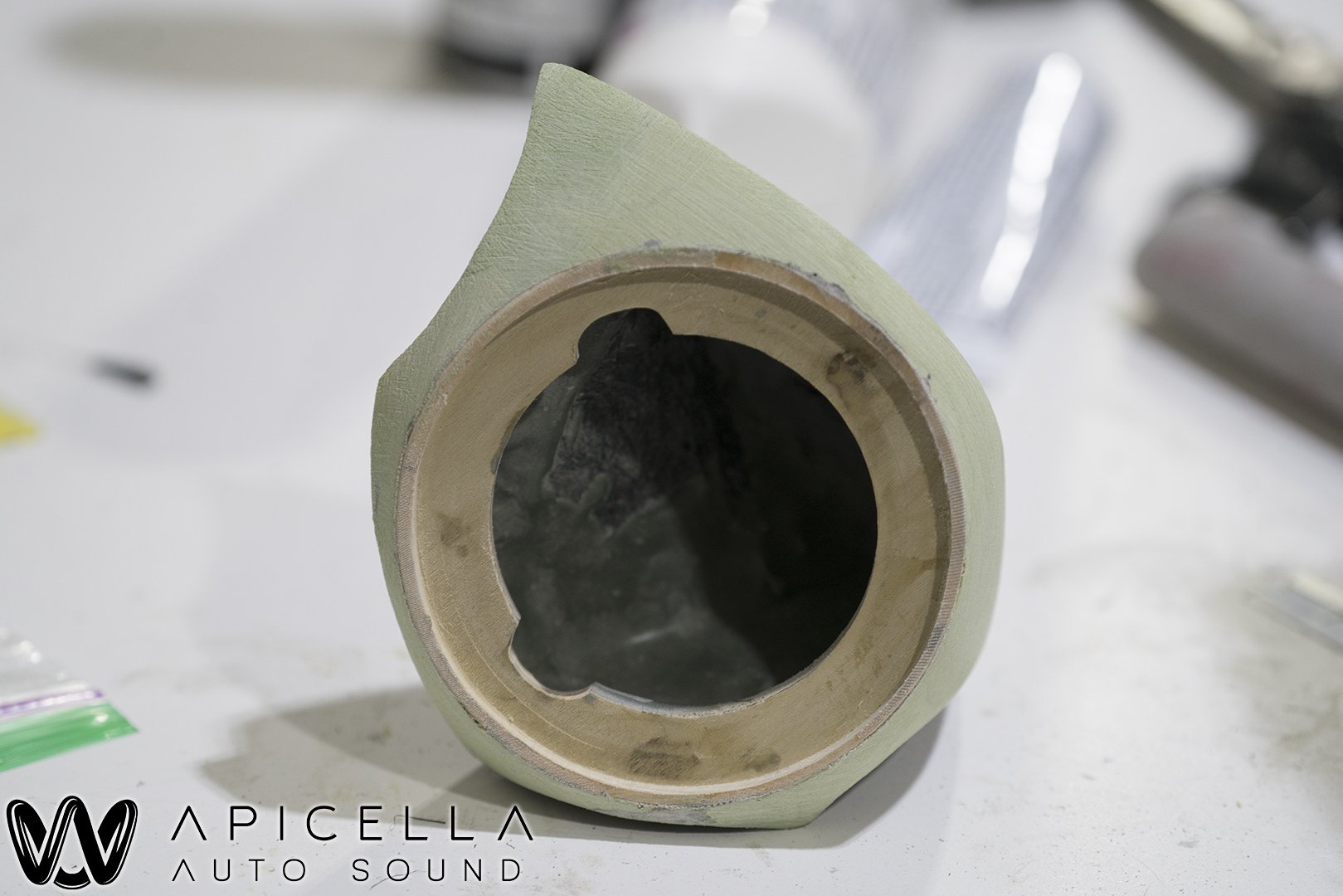

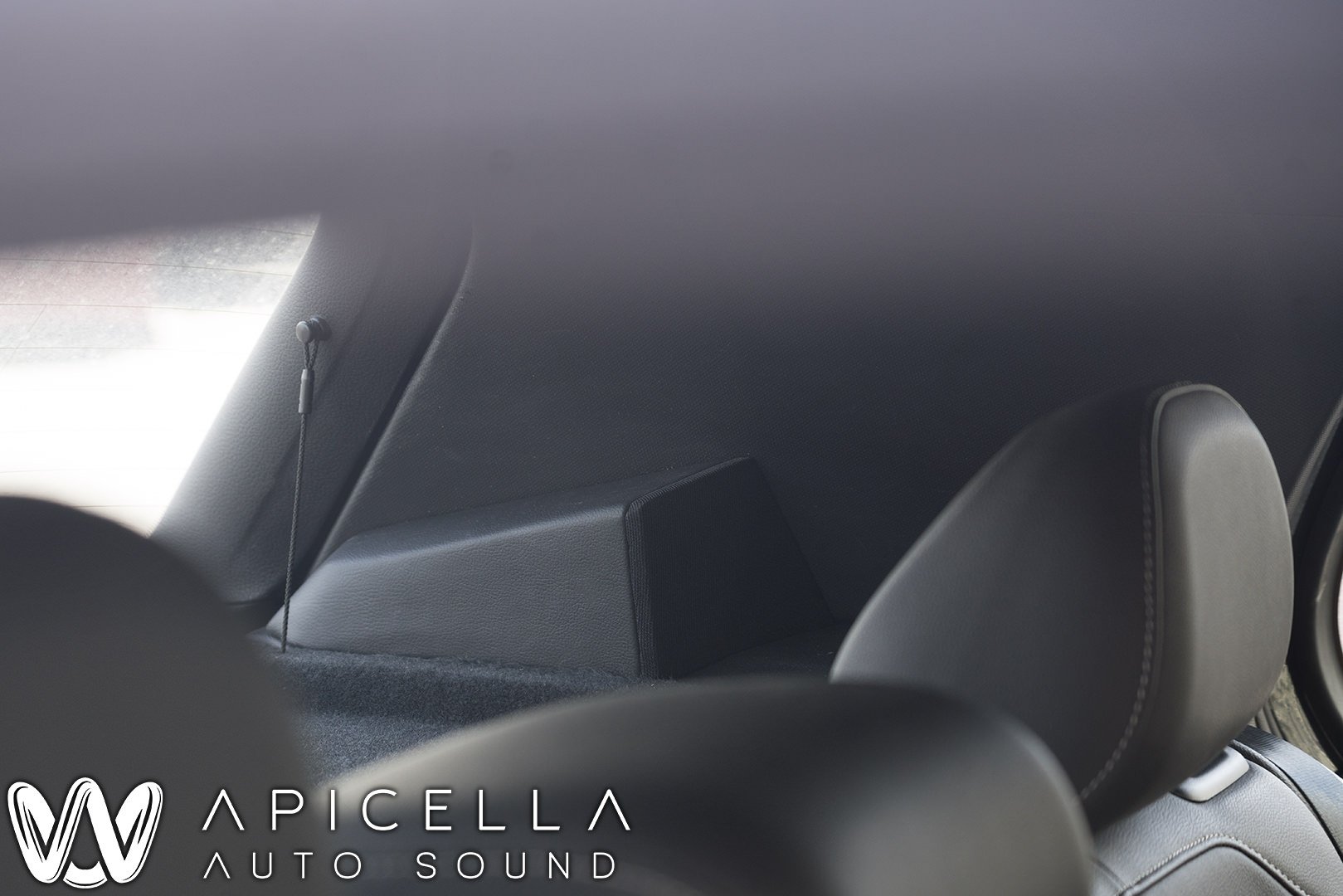

Test fit of the driver side kick. behind the opening on the back of the mold you can see the hole that vents into its own enclosed airspace. The factory hood release was also retained.

The space between the kick and the brake pedal had an inconstant floor that wasnt the best to rest your foot on. To counter that, i made a filler piece that is much more stable and comfortable to rest your foot on. It was filled with glass mat filler.

http://www.caraudio.com/forums/car-audio-build-logs-cars-trucks-suvs/634060-2016-volkswagen-golf-r-rebuild-audiofrog-brax-helix-illusion-audio.html

Well, like most car audio fanatics hes back for more upgrades. This time its a front stage rebuild, rear fill, and a Sony RSX-GS9 with an iPad mini. The front stage now consists of Audio Development W800NEO 8" midbass in custom kick panels, Scanspeak 12m midranges in the A-Pillars, and Satori TW29BN-B tweeters in the sail panels. Rear fill is using 2" Tang Band full ranges. All of this was to be installed with complete accurate reproduction of the signal in mind. What you wont see in this build log is the small 2 channel Arc Audio "micro" amplifier to power the rear fill, and the JL Audio Fix which fixes the oem sources signal and converts it to digital. The purpose of this is to well, give us a predictable signal so the same tune can be used between the Sony radio and the oem radio. It also gave us a digital out which was needed since you cant use the low level and high level inputs at the same time on the helix.

Side note, i apparently formatted my SD card on my camera or misplaced some photos before saving them to my computer somewhere during the kick panel, rear fill and a pillar build. Sorry :/

First things first was the kick panels. Some carpet was trimmed on both sides, and wires/plugs were moved on the driver side. These kicks were great as the car had these "cubbies" right behind where the kicks are, and where your feet would be, and had holes leading right into them. Because of this no crazy mods or ridiculously sized kicks were needed to get plenty of airspace.

Like i said, i lost a lot of pics from the first few things in this build. Molds were made, baffles were cut and attached, kicks were glassed to withstand a nuke, and grills and their housings were made and attached. Here is the inner part of the grill being filled to assure a tight fit with no inconsistencies. After that the grill inserts were rabbeted to flush mount some steel grill to protect the drivers from wandering feet.

Test fit of the driver side kick. behind the opening on the back of the mold you can see the hole that vents into its own enclosed airspace. The factory hood release was also retained.

The space between the kick and the brake pedal had an inconstant floor that wasnt the best to rest your foot on. To counter that, i made a filler piece that is much more stable and comfortable to rest your foot on. It was filled with glass mat filler.